100%(3)100% found this document useful (3 votes)

1K views32 pagesShopNotes Magazine 27

Trabajos en madera

Uploaded by

pepgoteCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

100%(3)100% found this document useful (3 votes)

1K views32 pagesShopNotes Magazine 27

Trabajos en madera

Uploaded by

pepgoteCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

= Scraper Plane = Outdoor Finishes ® Picnic Table

= Pegboard Storage Rack ® Splined Miter Joinery

Issue 27 May 1996

rumen Donald B. Peochike

‘ern Tim Robertson,

assocurceoron Phil Totten

‘commmnurineeorons Vingcnt Ancona

David Sone

sreinscron Cary Ciiatenson

sewontuvernarone Kurt Schultz

Roger Reiland

Mati Histon

Coentiee rector Tad Kali Bre. Eire

Dong Hoke» Projet Daspn Dir: Ken

Dade» Se Proj. Dna Kent Wel = Shop

Manager Save Curtin Sop Coma: Stove

“otra +S Photographer? Crayola Engiand +

Buc Comen. Card Gordon Gales Ane,

Grephie'Dasy Dir: Satie Rider » Sew

‘Grephie Derigue Ca Glows Grophe De

ger Coat. Cor

Cireatioe Dstor Susan Du Bale Asistont

{ise De Toy DawallsSberption Managers

Sandy Haun, Pige Hopare saat Su pe

‘ue roel Nessun fp: Ren A Buca,

VP Pinning Pre Sen Maarty + Contr

lo: Rahn tatchinsn = Sr et Lara Tha

o"aapes Holly Laces » Prod Dies George

‘Chmlra Prof. Mor Carl Quijanos Bs.

Pack: Doles N. Liter » Prt. doa

‘Sayder™ Nes Adin Al Bares” Prof Deve,

[De Soy Monts» Ain, Att Cheryl

Le, Ja Fish « Recs Jeane Jean ©

Bly, Mao Ken Gti

Op Din Bib Raker st Dr Cia Sergi +

‘Meteiis Moe: Mar Mattes Cat Sort p=

“etalon «Warsow Super: Nate Seon

‘Buyer Lina Jon» Sytem Op. Tammy Av

1 Tom autor Rela Crom» Teck Supp

David Stone «Cut. Ser. Rep denier Mar

phy. Joy Rem, Sern Kena, Ana Cox, Ada

Besi. Kral Andres, Margo Pest» Ware

sonar Gna Shean, Chock Carin, Shia

(Carey, Late Pine, Sos Gia, Cth Stina

im oes

Seep fl ina tae ie A

‘Sierponn Sle uy 440. yt

=e Se

Saas sir

CORR ka

Cutoffs

't doesn't take much detective work

to identify the scraper I use in the

shop. It’s the one with the rusty thumb-

prints imprinted on the blade. While

the rust is just part of living ina humid

area, the thumbprints tell a much dif-

ferent story.

‘They're-a visual reminder of the eon-

stant (and tiring) hand pressure ittakes

to keep the seraper flexed when

smoothing a surface, Not to mention

the heat that builds up that ean make it

downright uncomfort-

able to hold.

SOLUTION. That's

why I was excited

when Ken (our de-

sign director) showed

ime the seraper plane

hhe was working on for

this issue. It holds a

seraper at a constant

angle and flexes the

blade at the samo

time. So T ean make thin, wispy shav-

ings with a lot less effort. And I don't

leave any fingerprints on the scraper.

SMALL PIECES, Because the seraper

plane is built up from pieces that are

quite small (see photo), one of the chal-

lenges isto find a safe and accurate way

tocut them. So even ifyou don't plan on

building the plane, it's worth taking a

look at the article on page 4 to cheek out

the tool setups and jigs we used to work

‘with the smnall pieces.

LARGE PIECES, Cutting lange pieces

also presents its share of problems —

especially on the table saw. For exam-

pile, think back to the last time you used

a miter gauge to erosseut a wide panel.

What probably happened is you had

to pull the miter gauge so far back in

frontof the saw that the head no longer

supported the workpiece. Or maybe the

end of the runner came clear out of the

ShopNotes

slot, Hither way, it makes it impossible

to get an accurate cut,

CUTOFF TABLE. This is where a slid-

ing cutoff table like the one shown on

page 16 comes in handy. Basically, it's

>big platform that works like a huge mi:

ter gauge. But what's different is you

can make extremely accurate crosseuts

‘on panels up to a Tull 24" wide,

Besides its extralarge capacity,

there were several othor things on my

‘wish list as the sliding table was in the

design stage. Like

having a fixed fence

(for 90° cuts) and an

adjustable fence for

making angled euts.

A stop block for mak-

ing repeat cuts accu-

rately. A replaceable

insert to reduce

chipout, And a...

ANTICIPATION.

Okay, Tl stop there.

‘The point is Took forward to each new

project like the first balmy days of

spring after a long winter. And it

doesn't always have to be a woodwork-

ing project.

ACHANGE. Recently, I've picked up

the responsibilities of Editor here at

ShopNotes, Although the job is new,

T've been around SkopNotes since Issue

No. 1,80 I feel right at home.

‘And T'm as excited about the upeom-

ingissues as when I first came onboard.

As always, well eontinne to feature the

practical tips and techniques, unique

project ideas, and unbiased tool re-

views that you've come to expect,

Inthe meantime, don't be a stranger.

Stop hy for a visit. Drop me a line (or

photo) about the latest project you're

working on, Or send along a tip that

you'd like to see published. T look for-

‘ward to hearing from you,

e Contents

Projects & Techniques

Scraper Plane Scraper Plane

Designed to hold an ordinary steel! scraper, this shop-

built plane makes it easy to get a smooth, uniform surface.

Splined Mitere________________8&

Here's @ simple technique that adds lots of strength to

your miter joints, Just rout a slot and glue in @ spline.

Picnic Table 10

With splined miters and a “shortcut” version of a mortise

and tenon, this good/‘eaking picnic table is but fo ast.

Sliding Cutoff Table ______________ 16

Cut wide giued-up panels or pieces of plywood safely and Splined Miters pages

accurately with this sliding cutoff table, And an adjust-

able fence allows you to make angled cuts as well

Drilling Holes for Screws. +32

There's more to driting holes for screws than meets the

@ eye. The keyis the size and sequence you dil he holes.

Departments

Great Tips

Plywood Tips _____________ 14

A collection of our best tips for working with plywood.

Sliding Cutoff Table page 16

‘The Small Shop

Fegboard Storage 24

Lots of storage ina compact space. That's the idea behind

the unique design of this pegboard storage system.

Selecting Tools

Quick Clamps_____________ 26

We test three different “quick clamps" and offer practi-

cal suggestions on which one to choose.

Readers’

Shop Solutions 28

Our readers otter their own shop-tested solutions to

some of the most commen woodworking pr

Redwood

Building a project out of redwood? Understanding the

e ditterent grades can affect both its cost and durability.

Finish Room

Outdoor Finishes _________ 31

A look at three finishes that resist the extremes of weather,

Pegboard Storage page

No. 27 ‘ShopNotes 3

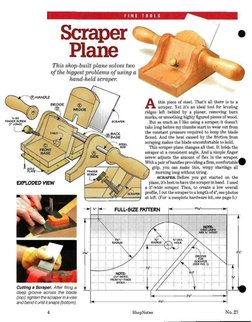

This shop-built plane solves two

of the biggest problems of using a

hand-held scraper.

Cutting a Scraper. Atter fling a

deep groove across the blade

(top), tighten the scraper ina vise

and bend it until it snaps (bottom).

4

thin piece of steel. That's all there ia to a

seraper. Yet it's an ideal tool for leveling

ridges left behind by a planer, removing burn

‘marks, or smoothing highly figured pieces of wood.

But as much as I like using a seraper, it doesn't

take long before my thumbs start to wear out from

the constant pressure required to keep the blade

flexed. And the heat eaused by the friction from

seraping makes the blade uncomfortable to hold.

‘This seraper plane changes all that, It holds the

seraper at a consistent angle. And a simple finger

serew adjusts the amount of flex in the seraper.

‘With a pair ofhandles providing a firm, comfortable

grip, you can make thin, wispy shavings all

) “morning long without tiring.

SCRAPER Before you get started on the

ne, it's best to have the scraper in hand, Tused

a B'-wide seraper. Then, to create a low overall

profile, I cut the scraper to a length of 4", see photos

at left. (For a complete hardware kit, see page 5.)

[= FULL-SIZE PATTERN, ">

‘ShopNotes No.27

ie

FINE

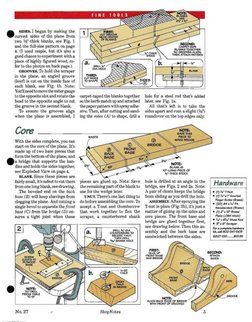

‘stpes. began by making the

Jeurved sides of the plane from

two Ve"-thick blanks, see Fig. 1

and the full-size pattern on page

4. (T used maple, but it also a

‘00d chance toexperiment witha

piece of highly figured wood, re-

fer to the photos on back page.)

‘GROVES. To hold the scraper

in the plane, an angled groove

(Kerf) is cut on the inside face of

each blank, see Fig. 1b. Note:

You'llneed tomove themiter gauge

tothe oppositeslotand rotatethe _carpet-taped the blanks together hole for a steel rod that's added

head to the opposite angle to cut sothekerfsmateh up and.attached later, see Fig. 1a

the groove in the second blank. thepaperpatternwithsprayadhe- All that's left. is to take the

‘To ensure the grooves align sive, Then, after cutting and sand- sides apart and rout a stight (14")

when the plane is assembled, I ing the sides (A) to shape, drill a roundover on the top edges only.

Core

With the sides complete, you ean

start on the core of the plane. It's

made up of two base pieces that

form the bottom of the plane, and

@& bridge that supports the han- x

dies and holds the sides together, IZ e

see Exploded View on page 4. s ‘a ONS ECE oF

BLANK. Since these pieces are ——_+

fairly small, it'ssafest toeutthem pieces are ghied up. Note: Save _ hole is drilled at an angle in the | Hardware

fromonelong blank,see drawing. theremaining partofthe blankto bridge, see Figs. 2 and 2a. Note: | "“@TAMATS |

‘The beveled end on the back use for the wedge later ‘A pair of cleats keeps the bridge | + (y y4°r me

base (B) will keep shavings from —‘ENUT. ThereSonelast thing to from sliding as you drill the hole, | * (4x7 Krued

clogging the plane. And cutting a do before assembling the core.Ty _ ASSEMBLY. After epoxying the

ingle bevel to separate the front accept a T-nut and thumbscrew T-nut in place (Fig, 2b), it's just a

base (C) from the bridge (D) en- that work together to flex the matter of gluing up the sides and

sures a tight joint when these seraper, a counterbored shank core pieces. The front base and

bridge are glued together first,

see drawing below. Then this as-

sembly and tho back base are

sandwiched between the sides,

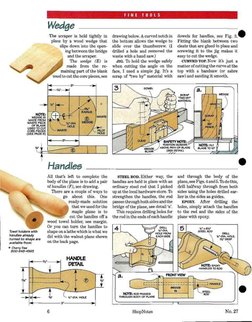

Wedge

‘The scraper is held tightly in

place by a wood wedge that

slips down into the open-

ing between the bridge

and the seraper.

‘The wedge (E) is

made from the re-

‘maining part of the blank

‘used to cut the core pieces, see

\

ee

drawing below. A eurved noteh in

the bottom allows the wedge to

slide over the thumbscrew, (1

drilled a hole and removed the

waste with a hand saw.)

5G. To hold the wedge safely

when cutting the augle on the

face, I used a simple fig. It's a

serap of “two by” material with

dowels for handles, see Fig.

Fitting the blank between two

cleats that are glued in place and.

serewing it to the jig makes it

easy to cut the wedge.

CURVED TOP. Now it's just a

matter of cutting the curve at the

top with @ bandsaw (or sabre

saw) and sanding it smooth,

3 owe

Handles

All that's left to complete’ the

body of the plane is to add a pair

of handles (F), see drawing.

There are a couple of ways to

go about this. One

ready-made. solution

that we used for the

maple plane is to

cut the handles off a

wood towel holder, see margin.

Or you can turn the handles to

shape on a lathe which is what we

did with the walnut plane shown

onthe back page.

STEEL ROD. Hither way, the

handles are held in place with an

ordinary steel rod that I picked

‘upat the local hardware store. To

strengthen the handles, the rod

passes through both sides and the

bridge of the plane, see detail ‘a’

‘This requires drilling holes for

the rod in the ends of each handle

NOTE: nar

sora

and through the body of the

plane, see Figs.4and5. To do this,

drill halfway through from both

sides using the holes drilled ear~

lier in the sides as guides.

EPOXY. After drilling the

holes, simply attach the handles

to the rod and the sides of the

plane with epoxy.

Gee

Sole Plates

At this point, all the wood parts

of the plane are complete. But to

protect the bottom of the plane

from wear, Ladded two brass sole

plates, see drawing.

‘These are 2"-wide strips that

are attached to the front and back

base pieces. (Brass strips are

available at many hobby shops.)

‘The strips are held in place

‘with small brass serews. Note: To

avoid splitting the wood, the

holes for the serews in the back

plate are located farther from the

inside edge, see detail ‘a.

COUNTERSINKS. To keep from

gouging the workpiece, the

serews are countersunk in the

sole plates. What works well here

{s to tighten a countersink bit in

‘The scraper plane

is easy to set up.

But first you'll

need to sharpen

the scraper,

SHARPENING, What you're af

teristocreatea"hook” orburr that

serapes the wood fibers, see draw-

ing above. Startby filing the end of

the scraper at about a 45° angle

(the exact angleisn't critical). Then

roll the edge with a burnisher or

hanlened piece of steel (ike a drill

bit) to form the bur:

the drill press and turn the chuck flush with the plane, see photo B.

by hand, see photo A at right.

FITTING. After screwing the using silicon-earbide sandpaper

sole plates in place, its just a mat- (upto 600;

ter of filing and sanding the edges of glass ensures a flat surface.

SETUP.Onee the scraper is

sharpened, you can set up the

plane. The quickest way I found

to do this is to place the plane on

aflat surface,

‘Then just slip the seraper into

the plane so the burr faces to-

lly, I sanded the sole flat

grit), see photo C. A piece

ward the back, see Step 1 below. A half turn or so after it contacts

‘And when the scraper “bottoms the scraper is just about right,

cout" slide the wedge into place, ‘The best vay to check is by

see Step 2, making a trial eut. Pushing the

‘All that's left now is to flex the plane across a board at an angle

scraper in a slight bow by adjust- should produee thin, lucy shav-

ing the finger screw, see Step 8. ings, see the photo above, &

2

Step 1. With the plane resting on a fiat Step 2. Now slide the wedge down Step 3. Turning the finger screw

surface, back off the finger screw and until its firmly seated between the flexes the scraperina slight bow which

slip the scraper in until itbottoms out. bridge and the scraper blade.

No. 27

‘ShopNotes

helps produce fine, wispy shavings

7

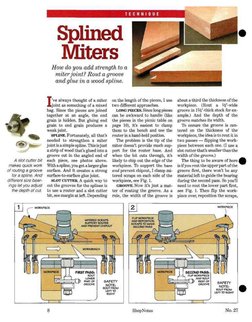

®

Assiot cutter bit

makes quick work

of routing a groove

fora spline. And

different size bear-

ings fet you adjust

the depth of cut

fe always thought of a miter

joint as something of a mixed

bag. Since the pieces are joined

together at an angle, the end

grain is hidden, But gluing end

grain to end grain produces a

weak joint.

SPLINE, Fortunately, all that's

needed to strengthen a miter

Jointisa simple spline. Thisisjust

astrip of wood that's giued into a

groove cut in the angled end of

each piece, see photos above.

With aspline, you get alarger glue

surface, And it creates a strong

surface-to-surface glue joint.

SLOT CUTTER. A quick way to

cut the grooves for the splines is

to use a router and a slot cutter

bit, see margin at left, Depending

Splined

Miters

How do you add strength toa

miter joint? Rout a groove

and glue in a wood spline.

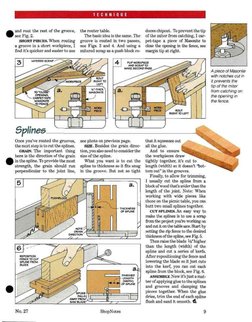

on the length of the pieces, I use about a third the thickness of the

‘two different approaches. workpiece. (Rout a \s'-wide

‘LONG PIECES. Since long pices groove in 1¥'-thiek stock for ex-

can be awkward to handle (like ample.) And the depth of the

the pieces in the picnic table on groove matches its width.

page 10), it's easiest to clamp To ensure the groove is cen-

them to the bench and use the tered on the thickness of the

router in a hand-held position, workpiece, the idea is to rout it in

‘The problem is the tip of the two passes — flipping the work-

titer doesn't provide much sup- piece between each one. (I use a

port for the router base, And slot eutter that’s smaller thanthe

when the bit cuts through, it's width of the groove.)

likely to chip out the edge of the The thing to be aware of. here @

‘workpiece. To support the base isifyourout the upper part ofthe

‘and prevent chipaut, I clamp mi- groove first, there won't be any

tered scraps on each side of the material left to guide the bearing

workpiece, see Fig. 1. during the second pass. So you'll

GROOVE. Now it’s just a mat- need Lo rout the lower part first,

ter of routing the groove, As a see Fig. 1. Then flip the work-

rule, the width of the groove is piece over, reposition the scraps,

ShopNotes No.2

aL

land rout the rest of the groove, the router table. duces chipout. To prevent the tip

see Fig. 2. ‘The basic dea is the same, The of the miter from eatehing, T eat

SHORT PIECES. When routing groove is routed in two passes, pet-tape a piece of Masonite to

fa groove ina short workpiece, I see Figs. 3 and 4. And using a close the opening in the fence, soe

find it's quicker and easier to use mitered serap asa push block re- margin tip at right.

A piece of Masonite

with notches cut in

it prevents the

tip ofthe miter

‘rom catching on

the opening in

the fence,

Once you've routed the grooves, see photo on previous page. that it equeezes out

thenext step istocut the splines, SIZE. Besides the grain direc- all the glue.

GRAIN. The important thing ticn,youalsoneed toconsiderthe And to ensure

here is the direction of the grain size of the spline. the workpieces draw

in the spline. To provide the most. What. you want is to cut the tightly together, it’s cut to

strength, the grain should run spline to thickness so it fits sug length (width) so it doesn’t “bot-

perpendicular to the joint line, in the groove. But not so tight tom out” in the grooves.

Finally, to allow for trimming,

I usually cut the spline from a

block of wood thats zoider than the

length of the joint. Note: When

working with wide pieces like

those on the picnic table, you can

butt twvo small splines together,

CUT SPLINES. An easy way to

make the splines is to use a scrap

from the project you're working on

and cut it on the table saw. Start by

setting the rip fence to the desired

thickness ofthe spline, see Fig. 5.

Then raise the blade Ys"higher

6b than the length (width) of the

} spline and cut a series of kerfs.

rerostron 5 After repositioning the fence and

Erne mo (SS lowering the blade so it just cuts

‘AY into the kerf, you ean cut each

os spline from the block, see Fig.

mesmo ‘ASSEMBLY. Now it's just a mat-

ina), |) ter of applying glue to the splines

e and grooves. and clamping the

Pica pieces together. When the glue

dries, trim the end of each spline

Saw aeave flush and sand it smooth.

No. 27 ‘ShopNotes, 9

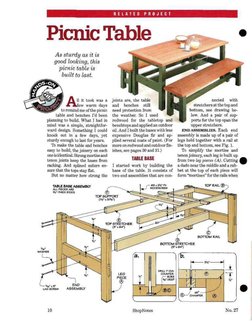

RELATED PROJECT

Picnic Table

As sturdy as it is

good looking, this

picnic table is

built to last.

Sey JN ii to0% was 0

Ss J few warm days

toremind me ofthe pienic

table and benches I'd been

planning to build, What I had in

mind was a simple, straightfor-

ward design. Something I could

knock out in a few days, yet

sturdy enough to last for years.

‘To make the table and benches

easy to build, the joinery on each

oneisidentical. Strongmortise and

tenon Joints keep the hases from

racking. And splined miters en-

sure that the tops stay flat.

‘But no matter how strong the

ar eNO

USsteew ASSEMBLY

10

Joints are, the table

‘and benches _ still

need protection from

the weather. So I used

redwood for the tabletop and

benchtops and applied an outdoor

cil. And I built the bases with less

expensive Douglas fir and ap-

plied several coats of paint. (For

‘more on redwood and outdoor fin-

ishes, see pages 20 and 31.)

‘TABLE BASE

1 started work by building the

base of the table. It consists of

two end assemblies that are con-

‘ShopNotes

nected with

stretchersat the topand

bottom, see drawing be-

low. And a pair of sup-

ports for the tap span the

upper stretchers,

END ASSEMBLIES. Each end

assembly is made up of a pair of

logs held together with a rail at

the top and hottom, see Fig. 1.

‘To simplify the mortise and

tenon joinery, each leg is built up

from two lag pieces (AJ. Cutting

‘dado near the middle and a rab-

het at the top of each piece will

form “mortises” for the rals when

No.27

RELATED PROJECT

Be.

(PRU INTERBORED SHAN HOME

(OP fROM BOTTOM BEFORE OUING

(eee rics)

“LEG PIECE

the legs are glued up.

RAILS. Each leg is held to-

gether with a narrow top rail (B)

and a wide bottom rail (C). Ten-

‘ong are eut on the end of each rail

to fit the mortises, see Figs. 1a

and Ib. And to aecept thestreteh-

ers, there are two shallow dadoes

in the top rail and a single dado

‘entered on the bottom rail,

To make assembly easier, two

counterbored shank holes are

drilled on each dado, see detail ‘a’

‘on page 10. And counterbored

shank holes drilled trom the bot

tom of the rails will be used to

attach the top, see Figs. 1 and 6.

Now it’s just amatter of gluing

upeach end assembly. To provide

plenty of working time (and pro-

tect against moisture), I used

slow-curing epoxy.

‘STRETCHERS. Tb hold the end

assemblies together, I added a

bottom (D) and two top stretchers

(&).Mfter euttinga pair of notches

ineach topstreteher to accept the

supports (added next), the

stretchers can be attached to the

end assemblies with lag serews.

TOP SUPPORTS. All that's left

to complete the base is to add

No, 27

two top supports (F). To provide

some extra knee room when sit-

ting down to a meal, the ends of

these supports are chamfered,

‘sce detail ‘b’ on page 10. Then the

supports are simply screwed in

place so the ends are flush with

the leg assemblies.

‘The bases for the twobenches are

built the same way as the table

base. But the size and number of

parts is just a bit different,

‘The biggest difference is the

leg pieces (G) are shorter, see Fig.

1. And unlike the table base, the

rails (H) that join the legs to-

gether are both the same width.

Another difference is the end

assemblies are held together

with two stretchers (1) instead of

three, see drawing below. And

both stretchers are the same

width. Here again, two notches

accept the top supports (J),

‘An easy way to

make one fong

pipe clamp is to

| thread the ends of

two shorter clamps

into a coupler.

(Eee ee

Guwees,

}

er crane

‘With the bases complete, you can

turn your attention to the table-

top. It consists ofa mitered frame

that surrounds several wood

planks, see Fig. 2

FRAME, The frame is made up

oftwoend (K) and two side pieces

(L) that are mitered at a 45° an-

fle, see Fig. 2. To strengthen the

miter joints, they're held to-

gether with wood splines. ‘These

splines fit in grooves that are

routed in the end of each frame

piece. (For more on making

splined miters, refer tothearticle

‘on page 8.)

In addition to the grooves for

the splines, you'll need to rout

two other grooves of the same

size."To accept the tongues on the

planks that are cut next, there's end pieces, see Fig; 2a.

groove inthe inside edge ofeach HAMPER. While I was at it, T

end piece, see Fig. 2. routed a decorative chamfer

PLANKS, With the frame com- (Yjo") around the top and bottom

plete, the next step is to cut the edgesofthe planks and the inside

planks (M) to length, see Fig. 2. edges of the frame pieces.

Rabbeting the end of each plank SPLINES. Before assemblingthe

on the top and bottom forms a tabletop, you'll need to make

tongue thatfitsthegroovesinthe the splines. I found it easiest to

‘Assembly. The first step is to epoxy two comers of the center of each tongue and slide the planks into the end of

frame. Clamping a spacer to the end of the frame and the frame, see middle drawing. Finally, with shims creating

positioning another clamp across the sides keeps the cor- an even gap between the planks, clamp the opposite end

ners square, see drawing at felt. Then apply epoxy to the of the frame in place, see margin and drawing at right

12

ShopNotes No.2

use the cutoffs from the top for

this. But since these pieces are

too narrow to span the length of

the joint line, you'll need to butt

two small splines together, see

Fig. 3.

ASSEMBLY. Now you're ready

to assemble the tabletop. Even

after dry assembling and check-

‘ing the fit, gluing up a large pro-

Ject like this ean be a challenge.

So I assembled it in stages, see

bottom of page 12.

‘There are a couple of things to

watch for here. To avoid filling

the grooves that the planks fit,

into, the splines are set back from

the inside corner, see Fig. 3a. And

to allow for wood movement, T

used shims to create a uniform

(4e" gap between the planks and

applied epoxy to the center of

each tongue only,

After trimming the splines

@ Assembly

‘At this point, all that’s left is to

attach the top ofthe table and the

benchtops to their bases,

‘TABLE. The easiest way to po-

sition the tabletop is to place it

upside down on the floor and cen-

ter the base on top oft, see Fig. 5.

After drilling counterbored

shank holes in the stretchers (E)

and countersunk shank holes in

the top supports (F), the top is

simply screwed in place, see de-

tails in Fig. 5. Installing serews

in the holes drilied earlier in the

top rails (B) secures the ends of

the frame,

‘BENCHES. Now it’s just a mat-

ter of attaching the two

bbenehtops. They're serewed to

the bases using the same basic

procedure as before, see Fig. 6.

CHAMEER. Thore's one last

thing to do, To prevent the legs

@ 20m plintering when moving

the table and benches, I sanded a

slight chamfer on the bottom

edges, see Figs. 5 and 6. &

No. 27

RELATED PROJECT

flush, there's just one more thing

todo. That's to “break” the sharp

edges on the top and bottom of

the table by routing 4" chamfer.

BENCHTOPS

‘The two tops for the benches are

built the same way as the table-

top. They're just smaller

While the end pieces (N) on the

denchtops are quite a bit shorter

than the ones on the tabletop, the

side pieces (O) are exactly the

same length, see Fig 4.

‘Here again, the mitered frame

for each benchtop is held to-

gether with splines, And a

tongue on the end of a single

plank (P) fits into a groove in

each end piece.

-#

Co

GreatPlywood Tips ¢

Here's a collection of tips that are

sure to come in handy the newt time

you're working with plywood.

Cutting Guide

‘mClamping a board to plywood exactly where you want can be a encethat indicates the path ofthe

ides the base ofa circular saw guessing game, To solve this, blade (or bit). So to ensure an

fr router 80 you can make a use acutting guide,see photos, accurate ent, just align one of the

straight cut, But positioningit on ‘The wayit works simple."The edges of the guide with the layout

the workpiece so the ent is made edges of the guide act as arefer- lines on the workpiece.

‘There's nothing complicated

about making the eutting guide.

Start out with an extra-wide base

made from ¥thick hardboard,

see drawing. After gluing and

serewing a plywood fence to the

base, one reference edge is cre-

ated by trimming off the waste

witha cireularsaw. Andthe other

SSS | bycuttingit offwithastraightbit

‘onsscao sase—m] ) | in a router e@

nore. “| ‘To use the guide, clump it toa

Taw sawoerourer | workpiace so the edge aligns with

en Gores Se thelayout marks. Then just make

a cut with the same blade or bit

that you used to create the refer-

tence edge. Note: Since a router

bit may not be exactly centered

inthe base of the router, keep the

same point on the hase against

the fence.

A Laying a sheet of foam insula ‘A By cutting an extra deep rab-

tion on the floor makes it easy 10 wicod, simply postion C-clamps bet, you can cenlera sorewon the

ccut.a full sheet of plywood down along the edge and use a wedge thickness of the workpiece. This

to manageable size. to apply pressure. way, it won't split out the side.

4 ShopNotes No.27

‘Few things are more frustrat-

ing than having a saw blade chip

cut the face veneer on an expen-

sive piece of plywood.

While a blade that’s specially

designed to cut plywood can pre-

vent this (see box at right), you

can also get good results with a

combination saw blade.

‘SCORE. One way Is to use the

saw blade to lightly score the ply-

wood, see Fig. 1, To do this, raise

the saw blade so it just barely

cuts through the face veneer and

make a pass,

‘This way, the blade severs the

‘wood fibers of the veneer instead

e Reducing Chipout_____|

of tearing them out, A second

full-depth pass completes the cut

and produces a crisp edge.

INSERT. Another way to get &

‘quality cut is to replace the origi-

‘nal metal insert on the table saw

withazero-clearance insert made

of wood, see Fig. 2

The basic idea here is to elimi-

nate the opening between the

blade and the insert by providing

support right up next to the saw

blade. This way, when the blade

cuts through the workpiece, the

insert backs up the bottom face of

the plywood and prevents the ve-

neer from splintering,

OE ET CES

‘One way to improve the quality of eut when

working with plywood is to use a saw blade

that's designed just for that. purpose.

‘To produce razor sharp cuts, both the 10"

table saw blade and 714° circular saw blade

shown here have 200 small stee]teoth sot around

the perimeter of a thin, tapered rim. A thick,

center hub adds rigidty to the blade,"

Note: To avoid binding, adjust

the blade height so only the

rim (not the hub) passes

through the workpiece,

Flush Trimming

W'To create the look of a solid

‘wood panel, the lip on a piece of

edging that stands a bit proud

needs to be trimmed flush with

the surface of the plywood,

PLANE. If there are only a few

pieces, I use a block plane to re-

‘move mast ofthe waste. To avoid

gouging the plywood, apply a

piece of masking tape and plane

until the tape starts to “fuzz,” see

Fig. 1. With the tape removed,

‘you can finish up with a sanding

block. Just sand until pencil

marks on the plywood start to

disappear, see detail.

ROUTER. A router and a flush

trim bit make quick work of the

Job if you have a lot of pieces to

trim, see Fig. 2. Clamping a serap

tothe workpiece keeps the router

from tipping. Anda rabbet in the

serap provides clearance for the

lip on the edging, see detail.

‘ShopNotes

15

Sliding Cutoff Table

Wide Panels. To make accurate crosscuts onpan- Angled Cuts. By attaching an adjustable fence

«8 up 1024" wide, this sliding cutofl table combines that pivots around the curved end of the siiaing

2 large plywood platform with a long fixed fence. table, you can make angled cuts as wel

can' tall you where its ex- easy to erosscut panels up to 24° ble has two “vero-clearance” in-

‘actly. But there'sa point of no wide, see topleft photo. And add- _serts that prevent chipout on the

return for the miter gauge on my ing an adjustable fence allows bottom of a workpiece. ‘To make

table saw. Especially when I pull you to make angled euts as well, this work for both 90° and 45° @

it back to erossent a wide panel. ee top right photo. ‘cuts, it's just a matter of remov-

It’s the point where the hes STOP BLOCKS. Whether you ing one insert and replacing it

starts to wobble because therun- make straight or angled cuts, with another, see photo B.

ner isn't fully supported in the sometimes you need x number of SAFETY. Finally, a pair of wood

miter gauge slot, And that makes pieces thatareidenticalin length, blocks (see inset photo below)

‘it almost impossible to crosseut a To ensure accuracy, a pair of stop work together to stop the table at

wide panel safely and accurately. blocks that slide in T-shaped slots the end of a cut. This “buries” the

‘That's why I built this sliding in the fencescan be lockedtightly _ blade in a thick

cutoff table. With the workpiece in place, see photo A. block on the

resting on a lange platform that INSERTS. In addition to the back of the ta-

slides across the saw table, it’s stop blocks, this sliding eutoffta- ble, see photo C,

A. Stop Blocks. A pait of stop blocks B, Inserts, Tworomoveable nserts(one C. Safety System. A thick wood block

allows you to Cut multiple pieces to for90"and the other for 45" cuts) reduce and two stops prevent the blade from

iength quickly and accurately. ‘chipout on the botiom of a workpiece. being exposed at the end of a cut

16 ShopNotes No.2

ae

‘OVERALL DIMENSIONS:

@& Pee toew raze

Soe

sath)

nscer

| Hardware

A Large Bave (1) 2tex27-9A Py. (00) te" Threaded

& Small Base (1) 22x58 -% Py, cai |

C Insert Plates (2) 6x26-% Ply. oiler Botte

D Runner (1) Yex%s-2%2 -eaeene

E Front Face (1) YexB2-16 Threaded Knbe

F Insert Blocks (4) SxB¥e-10 + aerate

G Short End Blocks (8) YaxBl2-3 Tiraadad Kobe

H Back Face (1) aeaaia es 9 Get rants

1 Long End Block (1) Ya x BV2- 25 } *

J. Top Fieces (2) Vox2-1% ies raster

k Stops (2) Yox2-3%e Woodscrews

L Fence Pieces (2) Vax Be-32 © (4) #8 x2" Fh

M Mounting Block (1) Sota ete

N Spacer (1) Wena -Yo Mas. s a

e oan) ee ‘, mie aii

P ouppore (1) axe s8 order a complete

@ Blade Guard (5) %x3%4- 52 bach ica

R Stop Blocks (2) Saxtle-4 Se eee Sok ee

No. 27 ‘ShopNotes 7

To builel accuracy mf

into the siiding

table, check that

the corner of the

large base piece

Js square, and the

miter gauge stot

is parallel to

the blade.

To installa

threaded insert,

chuck a cutoft bolt

with two nuts tight-

ened against each

other in the dlril

press, Then turn

the chuck by handl

FEATURE PROJECT

T began work on the cutoff table

by building a plywood base. Tt

serves as a platform that carries

the workpiece through the blade.

‘The base is made up of three

parts: a large (A) and small base

(B) piece with a removeable in-

sert plate (C) sandwiched in be-

tween, see Fig. 1. Note: To make

straight and beveled cuts, Tmade

two insert plates.

CURVE. To keep the adjustable

fenee (added later on) from bind-

ing, there's a curve cut on the

outside comer of the large base

piece, see Fig. 2. This requires

establishing a pivot point for the

fence, then cutting the curved

shape and sanding it smooth.

RUNNER.The base is guided

bya hardwood runner that slides

fa

in the miter gauge slot. To pro-

duce aceurate cuts you'll need to

‘make sure this slot is parallel to

the blade.

‘The runner fits in a dado eut in

the bottom of the base. When lay-

{ng out the location of this dado,

the idea is to have the blade cut

through the center of the insert.

‘Todo this, place the base piece on

the saw table 3° away (half the

‘width of the insert) from the cen-

ter of the blade, see Fig. 2a. Then

mark the location of the dado by

using the slot as a reference.

Before cutting the dado, it's

best to have the runner (D) in

hand. It’s a piece of hardwood

(maple) eut to fit the miter gauge

slot s0 it slides amoothly without

any “play”, see Fig. 2b.

‘THREADED INSERT. After cut-

ting the dado and screwing the

runner in place, all that's left is to

install athreaded insert, see Fig.

3 and margin at left. It fits in a

hole that's drilled at the pivot

point for the adjustable fence,

2

18

ShopNotes

ae)

Fixed Fence & Support Rail

‘The base is held together with

two parts, A fixed fence runs

across the back edge and sup-

ports the workpieee as you make

a cut, see Fig. 4. And a support

rail adds rigidity to the front.

POCKET. To slip the inserts in

‘and out of the sliding table, the

fence and support rail each have

“pocket” that's built up from%4"-

thick hardwood blocks (maple

‘To form this pocket in the sup-

port rail, a front face (B) is cut to

length, see Fig. 6, Then an insert

block (F) is sandwiched between

two short end blocks (G),

Except for its size, the fence

isn't all that different. But here,

there's a long back face (H). And

another insert block (F) fits be-

tween the short end block (G) and

along end block ().

‘TSLOT. Before assembling all

these pieces, a T-shaped slot is

cut in the fence for a toilet bolt

that Jets you adjust the stop block

{added later). Making this slot is

simple, First, cut a shallow

‘groove in the back face (FD and a

deeper groove in the long end

block (1), see Fig. 5a. Then rabbet

the top edge of the longend block.

ASSEMBLY.T) assemble the

fence and support rail, the end

blocks only are glued in place. (L

used the insert blocksas spacers.)

When the glue dries, the fence

is screwed (not glued) to the hase

pieces so it's square to the blade

and flush with the back edge. And

the support rail is serewed flush

with the front edge.

INSERTS. At this point, the in-

sert: plates (B) and insert blocks

(F) can be serewed together to

form the inserts, see margin

‘They're held in piace with knobs

that tighten into threaded in-

serts, see Pigs. 4 and 5,

STOPBLOCK. All that's left is

to add a stop block. It consists of

atop piece (J) and stop (K) glued

up in an L-shape, see Fig. 6.

‘Tightening a knob on a toilet bolt

that passes through the top piece

holds the stop block in place.

5

With two inserts, you

‘can use one for 90°

cuts (lop) and the

‘other for 45° cuts

(bottom).

Adjustable Fence

At this point, the cut

off table can be used

for making 90° cuts.

But to make angled

cuts as well, T added

fan adjustable fence

with a simple clamp

that locks it in place,

seo Fig. 7 and photo.

TSLOT. Like the

fixed fence, a T-slot

for astop block runsalong the top

edge of the adjustable fence. Af-

ter cutting two %4"thick fence

pieces (L) to size, this T-slot is

made the same way as the one in

the fixed fence, see Figs, Sand Sa,

‘NOTCH. Once the fence is glued

uup, a noteh is cut at one end. To

providea pivot point that lets you

swing the fence to the desired

angle, a knob passes through a

hole drilled in the notch and into

the threaded insert installed ear-

lier, see Fig. 7a. Tightening (or

Toosening) the knob lets you at-

tach (or remove) the fence.

‘CLAMP. Now you can add the

lamp. Tt consists of three parts:

a mounting block and arm made

of hardwood, and a Masonite

spacer in between, see Fig. 7b,

‘What makes this clamp workis

the mounting block is thinner

than the base, This way, the

7| seae TOP Lock

SEER et eB

Me

o

wien

posusras.e

rence

nese

mec Ra.

é i

a. b. mone

=e \

Fe

}

J

Bee =

Tags >

oe ee = /

Dancin

ermoren) e

spacer ereates a small gap that

allows the arm to pinch against

the base of the cutoff table when

‘you tighten the lamp.

To provide this clamping pres-

sure, the mounting block (31) and

spacer (N) are first glued in

place, see Fig. 9. After installing

threaded insert in the mounting

block and attaching the erm (O)

‘with serews,a simple knob ean be

used to tighten the clamp, see

Fig. 7b,

Finally, it's just a matter of add-

ing'a second stop block for the ad-

Justable fence, see Fig. 7,

ShopNotes:

No.27

Stop System

‘Al that’s left to complete the slid-

ing table is to add the stop system.

Besides supporting the sliding ta-

ble, it covers the exposed part of

the blade that passes through the

fixed fence at the end of a cut.

‘To make this work, the stop

system consists of three parts: a

support, a blade guard, and a pair

of stop blocks, see Figs. 10, 11,

and photo Con page 16.

‘SUPPORT. The siepport (P) is &

long strip of wood that attaches

to the extension wing of the table

saw, see Fig. 10. It prevents the

sliding table from tipping at the

‘beginning and end of a cut.

‘To determine the length of the

support, simply measure the

dopth of the saw table and add

12". This gives you 6" of support

at each end.) After cutting the

support to length, it's just a mat-

ter of bolting it flush with the top

of the saw table, see Fig. 10,

BLADE GUARD. Now you can

add the blade guard (Q), see Fig.

11. It's a thick block that's made

by gluing up five pieces of 34'-

thick hardwood. In use, the part

of the blacle that cuts through the

back of the fence is “buried” in

this block at the end of a cut.

Before attaching the guard, 1

cut Yyr-wide chamfers on all the

outside edges. Then the blade

‘guard is glued in place so it’s cen-

tered behind the insert,

‘STOP BLOCKS. The last thing

todoistoadd two stop blocks (A).

‘These blocks prevent the blade

from catting through the blade

guard by creating a positive stop

at the end of a cut. One block is

‘glued and serewed to the end of

the support, see Fig. 10. The

other attaches to the bottom of

the cutoff table, see Fig. 12.

‘To determine the location of

this block, position the cutoff ta-

ble on the saw so the front of the

fence is centered over the saw

arbor, see Side View. Then giue

and serew it in place. Note: An

Us" gap between the block and

support keeps the table from

binding, see End View. #&

12 NOTE Revove nsec >

SAWBLADE TO SEE ARBOR

No. 27

‘ShopNotes

IN THE SHOP

etter

Jn the surface, assembling a

roject with screws is

fairly straightforward, Just drill

a hole (or a series of holes) and

drive in the serews.

Maybe that's why

ittsso frustrating when

things don't go exactly

as planned, For exam-

ple, the serew doesn't

raw the pieces tightly

together. Or the head

ofthe serew snaps off,

If something like

‘that happens, it’s only

natural to blame the serew. But

more than likely, thereal problem

‘ean be traced back to the holes

that were drilled for the serews.

‘So when working with stand-

‘ard tapered woodserews, I drill a

series of stair-stepped holes to fit

tthe shape of the serew as closely

as possible, This can either be

done with individual deil bits. Or

you can use a special combination

bit, sce right-hand box on page 23.

‘TWO HOLES. Toensureasmooth

assembly and a joint that's held

tightly together, I start by drill-

ing two holes, A large siank hole

‘goes all the way through the top

piece, see photo above and draw-

ing in margin, And a small pilot

hole stopsin the base piece. Note:

‘To drill these holes as accurately

as possible, I use brad point bits.

SHANK HOLE. The shank hole

provides clearance for the

‘smooth part of the screw. And it

keeps the threads in the top piece

from “catching” and creating a

2

gap between the pieces, see Fig. 1. the pilot hole ix to prevent. the

SIZE. Aneasy way toselect the wood from splitting.

right size drill bit for the shank To do this effectively, the pilot

hole is to hold the serew in front hole has to be sized correctly. If

ofthe bit, see Fig.2a. Thesidesof it'stoolarge, the holding power of

the bit should just barely stick the serew is reduced. Too small

out pasttheshank.’Thenwhen you and it inereases the chances of

drill the hole, the screw will slide splitting the wood or snapping

through without binding, see Fig.2. the head off the screw.

PILOT HOLE. The next step is As a rule, I drill the pilot hole

to drill the pilot hole in the base slightly smaller than the root of

piece. The most important job of the screw (the part of the screw

ShopNotes No.27

@ write the shank hole and pilot

NTH

botwoen the threads). This gives [4

the threads something to grab, |")

Countess ort CENTERS

ROE ON SHANE ROLE

‘Here again, to find the correct

size drill bit, line up the bit with

the screw. But this time, place the

serew behind the bit, see Fig. a.

‘The root of the screw should just,

peek past the sides of the bit,

=

morno

i=

i

DEPTH. Another thing to keep

jn mind is the depth of the pilot

hole. This will vary depending on

whether you're working with

hardwood or softwood,

Since hardwood is more likely

to split, [drill the hole almost as

deep as the screw will penetrate,

cet

see Fig. 3. Leaving two or three

threads to bite into the wood is

plenty to produce a solid grip.

But with softwood, 1 drill a

shallower hole — usually about

half the length of the threaded

part ofthe serew that will bein the

base piece,

APPEARANCE

down tight.

hole take care of the basic me-

chanies of a serew joint, you also

pearance of the serew head.

projects, I drill a countersink

‘This leaves the screw head ex-

TCLS Ue LSS

There's a big difference in these two counter-

sink bits. One uses a single cutting edge that

slices the wood fibers and leaves a clean hole,

see left-hand photo. ‘The other has multiple

utters that serape the wood and produce a

scalloped cut, see right-hand photo.

‘The important thing is to drill

the countersink after the shank

hole and pilot hole, see Fig. 4.

‘This way, the tapered sides of the

bit automatically center it on the

shank hole. (For more on coun-

need to consider the finished ap-_tersink bits, see box below left.)

COUNTERBORE. Fora finished

‘COUNTERSINK. On most shop appearance, a counterbore lets

‘you recess the verew head below

the surface, This is a deep,

posed and set slightly below the straight-sided hole that's drilled

surface. The beveled sides of the

countersink match the shape of

the screw head so it can draw counterbore is drilled before the

to accept a wood plug or filler.

‘The thing to be aware of is the

sshankchole and pilot hole, see Fig.

5, (Ifyou drill the shank hole first,

the bit will wander because there's

no centerpoint to guide it.)

'So which bit do you use to drill

1 counterbore? Since a twist bit

also forms a countersink at the

base of the hole, it's « good choice

for flathead woodscrews, see Fig.

6. But for a roundhead screw

that's at on the bottom, 1 use a

brad point bit. &

TEC

Ityou're installing alot of screws, thistapered

combination bit saves time by drilling a series

of holes in a single operation, You can use it to

Grill the countersink, shank hole, and pilot

hole, see left-hand photo. Or adjust it to drill

the counterbore as Well, see right-hand photo,

¢ J

|

ShopNotes 23

To set the screw

head just below

the surface, oil

the countersink

deep enough so

the head fits the

top of the opening,

Sources

“*Wooderat (single

mutiple cutee cour

‘ersink, com bite)

200226:163

* Garrett Wade (com

‘ination bis)

200-221-2942

1 Woodworker Supply

(ingle cutter cour

torink, comb i)

200-648-0292

* Conscantines (mut

{ipl cutter counter

‘toh, comb ie)

(200-225-8087

Just open the

doors to find

the hidden

storage space

inside this

compact rack.

ree

t first glance, it’s hard to

ine that you can or-

‘anize a wall full of tools in this

compact storage rack, see photo.

But a closer look reveals the “hid-

den” storage space inside.

This extra storage is provided

by two doors that have pegboard

‘onboth the frontand the back. To

provide easy access to tools on

‘each side, the doors swing out in

opposite directions, refer to the

photos on the back page.

FRAME, The doors are sup-

ported by a sturdy frame made

from “two-by” material (I used

Douglas fir) and a %4"-thiek ply-

wood top and bottom, see draw-

ing below left. It’s held together

with simple (yet strong)

lap joints that are madeby ~~

cutting a series of notches

{in the frame pieces.

A pair of stretchers (A)

used to attach the rack to

the wall are rabbeted on

each end, see Pig. 1. These

rabbets fit dadoes in the

back of the two uprights

(B). Another pair of dacloes on the

inside face accept short. arms (C)

that are rabbeted on one end.

Before assembling the frame,

it’s easiest to drill a hole in each

‘arm for a pin that will allow the

doors to pivot, see Pig. 2. And a

shallow groove is cut for the top

‘and bottom that are added later.

ASSEMBLY. Now you can as-

semble the frame. The stretch-

ers, uprights, and arms are held

together with glue and screws,

‘To add rigidity to the frame,

the plywood top and bottom (D)

are cutto fit between the grooves

in the arms. But before gluing

and serewing them in place, 1@

moaemens °

‘added hardwood trim strips ()

‘to cover the front edges.

With the frame complete, you can

add the doors. They're just sim-

ple wood frames with pegboard

‘on each aide, see Fig. 3.

‘The overall height of the doors

is the same. But the back door is

1" narrower so it swings past the

front door when you open it, see

Fig. 84.

Determining the length of the

frame pieces is easy. The stiles (F)

‘oneach door are identical in length.

(To provide an 14" clearance at the

top and bottom, T cut them 36"

long.) But the front rails (G) are

1" longer than the back rails (H).

(This takes into account the over

all width of the doors and the,join-

‘ety that holds them together.)

With the frame pieces cut to

length, matching rabbets are cut

on both sides for the pegboard

panels, see Fig, a. And anotch in

the ends of the stiles accepts the

rails, see Fig. 3b,

PANELS. After screwing the

frame pieces together, its Just a

matter of entting front (1) and back

door pamels (J) to fitand screwing

them in place, see Pig. 3c. And a

serap pull (K) is glued to the

front of the back door. door, see Fig. 4. and 4a. ‘These place, a hole is drilled in each up-

ATTACH DOORS. All that's left bolts pass through holes in the perarm fora spring loaded catch,

isto attach the doors. They pivot arms (drilled earlier) and thread see Fig. 5. Note: One catch

‘on two hex bolts that pass into into 'Enuts in the inside face of mounts to the baek of the front

bronze bushings installed in the the arms. door. And the other'ison the front,

top and bottom edges of each Finally, to lock the doors in of the back door, refer to Fig. 3. Hardware

(2) 89 14 P he

© (20) 70129" Fine

© (0) 20x14" Pauw

(60) 0 2) Pe

© (a) 42 HecBolee

© AW Fue Washes

1 (6) Fender Washoe

Strout

8 eyes enp

Brose Bushings

# (2) Letetond Spr

rad

SELECTING TOOLS

Quick Clamps —

: Inere’s one thing that's al-

Prices ays in short supply when

clamping up a project — a third

wove hand. With one hand positioning

fe'camp: $12.95 | the clamp, and the other keeping

22" clamp. p38 | the parts aligned, an extra hand

2" camp 918-95 | to tighten the clamp would speed

Quick-Grip_ | things up considerably,

ene: sabe ‘That's where these quick

olan clamps come in, see photos below

Sorcame gosee | and prices in margin. They free

| ia up one hand by allowing you to

Pillck- Star | position the clamp and apply

Quic!

(American Tool)

800-767-6297

pressure with the other hand.

But there's more to @ clamp

than how handy itis to use. Tosee

how they performed when gluing

up a project or making @ tool

setup, we ran the clampsthrough a

series of tests, see photos above.

To provide a range of view-

points, we asked three wood-

workers with different amounts

of experience to test the clamps:

Cary (a weekend woodworker),

Steve an advanced woodworker),

Gar meas

and Ken (a professional earpen-

ter and cabinetmaker).

BB These clamps look quite differ-

‘ent from each other: Do they work

differently too?

Steve: The two clamps that are

the most alike are the E-Z Hold

and Quick-Grip. With these, I

Just squeeze the handle to slide

the lower jaw along the bar until

it's tight against the workpiece.

Ken: While both clamps use a

pumping action to advance the

Jaw, [liked the in-line handle on

the E-Z Hold the best. (See the

top drawing at left.) That's be-

cause no matter how the clamp is

oriented, it's convenient to use.

But since the pistol grip on the

Quick-Grip is perpendicular to

the bar, it ean be awkward to use

depending on the position of the

clamp. (See enter drawing.)

Cary: The Quick-Star tises a

different approach altogether.

‘The lower jaw on this clamp is

spring-loaded, 30. it advances

“automatically” like a tape meas-

ure, (See bottom drawing.)

Bi How does that work?

Cary: It's pretty simple really,

Pulling the lower jaw down the

bar applies tension to the spring.

And releasing it retracts the

spring and pulls the jaw against,

the workpiece.

Once the jaw is snug, it works

like. standard bar clamp. As you

No.27

tighten the handle, a screw ap-

plies the clamping pressure.

Which is why the Quick-Star ap-

plies more pressure than the other

two clamps. (See drawing and

photo above right)

‘Ken: But that's not to say you

can't get a tight fitting glue joint

with the E-Z Hold and Quick-

Grip. Since they don’t produce as.

much clamping pressure, the key

@ is tomake sure the joine fits tight

before gluing the pieces together,

‘And since I do that anyway (even

Clamp Pads. The large jaws

and the soft rubbery clamp pads

on the E-Z Hold (left) and Quick-

Irregular Shapes. Unlike the Quick-Grip (left), the

clamp pads on the Quick-Star (center) and E-Z Hold

(ight) make full contact with iregular-shaped objects.

when using heavy-duty clamps),

that’s not a big deal.

BE What about the clamp heads?

Cary: That's one of the biggest

differences I noticed. Because

both clamp heads on the Quick-

Grip are fixed, the pads don't

make full contact when I campan

irregularshaped object. (See

photo above left.)

Bat the lower clamp head on

the Quick-Star is basically just. a

ball and socket joint. So the head

Grip (center) provide a more sta-

bie grip than the smaller plastic

pads on the Quick-Star (right)

Clampi

Pressure.

pivots as I tighten

the clamp and the pads conform

to the shape of the object.

Steve: While it doesn’t have

quite as much flexibility, the up-

per clamp head on the E~Z Hold

also pivots.

In fact, the whole upper jaw

slides off the bar so I can use it as

a spreader, That's handy when

need to take a project apart after

dry assembling it to check the fit,

(See margin.)

WOne last question. Besides the

color, are there any real differ-

ences between the clamp pads?

Steve: Size is one thing. The

large pads on the E- Hold and

Quick-Grip seemed to distribute

pressure farther along the joint

line than the small pads on the

Quick-Star; (See photos at left.)

Cary: And I liked the positive

grip provided by the soft, rub-

bery pads on both the B-Z Hold

and Quick-Grip.

Cary: Choosing the best quick

clamp was a tug of war.

liked the spring-loaded jaw

and the extra clamping pressure

‘you get with the Quick-Star. But

not enough to pay over $20 for it,

So I pieked the E-Z Hold in-

stead. It only costs about half as

much, And it would easily handle

most of my clamping needs.

No.27

Recommendations

Steve: At first, it was the low cost

of the E-Z Hold clamps that

‘aught my eye too. (Especially if

‘you're buying a bunch of elamps.)

Butthe real reason I picked the

E-Z Hold was the convenience of

the in-line handle. Also, convert-

ing the clamp to a spreader is

‘something that would come in

handy for me once in awhile,

ShopNotes

Ken: I guess that makes three of

us, Although it doesn’t produce

as much clamping pressure, T

chose the E-Z Hold too.

It exerts plenty of pressure if

you start with a tight-fitting

joint. And the large clamping sur-

face provided by the soft, rab-

ery pads distributes pressure

evenly along the joint line. &

27

Pressure. With a

pressure gauge

‘mounted ona

hydraulic cylinder,

we measured how

much pressure each

clamp applied.

4

_ =

Simply reversing

the jaws on the

E-Z Hold clamp

allows you to use

itasa spreader,

[ire ma Lk eas

ShopSolutions °

A

Like many woodworkers, Tuse

a shop-made “sled” to rip a

‘straight edge on rough cut lum-

ber, But rather than buy special

clamps to hold boards securely to the base of the sled, see drawing. and glued sandpaper to the base.

the sled, a pair of spring-loaded And the other fastens toa board —_Andastop ghied and serewed to

hinges applies all the pressure I that acts as a hold-down, the end of the base helps push the

need, see photo. ‘To hold the workpiece securely worlspiece when making a cut.

One leaf of each spring is at- in place, I screwed rubber “feet” Terry Vikla

tached to a rail that’s serewed toto the bottom of the hold-down Cottage Grove, Minnesota

Brad & Nail “Drill Bit”

| Predrilling a pilot hole for a [_ _

‘brad or finish nail helps prevent | Bead'on wat

them from splitting the wood. | SANSEUsD

But Idon'talways have drill bit | terre

that's the same size as the brad or

finish nail,

‘Todrill holes that are the exact

size, I cut the head from one of the

‘brads ornails I'musing and chuck

‘the shank in my drill. The shank

works like a drill bit to drill a hole

that fits the brad or nail perfectly.

David Krimmel

San Diego, California

28 ShopNotes No, 27

emake

Quick Tips

A Since his lip balm is always

hanay. Bill Johnson of Akron,

Ohio, applies it to screw threads

lomake the screws easy to drive.

Finishing Easel

=n

To make it less tiring on my

back when finishing doors and

other flat projects, I built an

“easel” that holds the workpiece

‘ata comfortable height, see photo.

‘The main parts of the easel are

apair of uprights made from “two

by” material that are set up on a

sawhorse, see drawing. A square

notch in the bottom of each up-

right fits behind a stretcher

serewed to the legs of the saw-

horse, see detail 'b’. And an an-

gled notch in the back edge

determines the slope of the easel.

‘To keep the uprights from tip-

pping, I drilled two holes in each

one for a pair of long dowels. By

gining and serewing one end of

No. 27

4A To increase the grip of his push

block, John French of San Di-

go, California, glues shalt liner

10 the bottom of the block.

each dowel to the same upright,

‘you an slide the other one on the

‘dowels to adjust the easel for pro-

jects of different widths.

Finally, a dowel in the front edge

ofeach upright supports the work

piece. And a piece of PVC pipe

that’s cut in half Cengthwise) and

serewed to the uprights keeps the

wet finish on the project from

sticking to the easel, see detail ‘x’

‘Allan Gabel

Sussex, Wisconsin

‘ShopNotes

> Right out =

of the pack. (=

age, t'seasy \

to identiy the <<)

grit on a hook and

loop. sanding disk.

Butif'you change disks fre-

quently, the grit markings on

‘Back soon wear ott

‘So Wayne Loper of Duncar-

nan, Pennsyivania, uses a per-

‘manent marker to label the griton

the one place on the front of the

disk that doesn't clog or wear

out — the center of the disk

If you'd like to share your original

solutions to problems you've faced,

send them to; ShopNotes, Attn: Shop

Solutions, 2200 Grand Avenue, Des

Moines, 1A 50312. (Or if it's easier,

FAX them to us at: 515-282-6741)

‘We'll pay up to $200 depending on

the published length, Please include

a daytime phone number so we can

call you if we have any questions,

Redwood

T=: 8 good reason why the houses my

grandfather built still have their original wood

siding. The siding is made from redwood.

‘And even though the finish on many of those

homes has deteriorated over the years, the red-

‘wood is still as solid as the day he nailed it in place.

‘That's because redwood has a natural resistance to

both insects and decay.

Because of this durability, redwood is an ideal

wood for a project that’s going to sit outside (ike

the pienic table on page 10). But to take advantage

of its ability to fend off damaging inseets and rot,

you'll need to take a close Jook at the different

ides of redwood.

‘TWO GROUPS. Although there are a number of

different grades, each one falls into one of two main

‘groups; Heartwood or Sapwood.

‘When buying redwood for an outdoor project, I

make ita point to select Heartwood lumber, Heart-

Wood is easy to identify by its reddish-brown color,

see photos at right. But there's

something about. it that’s even

more important than eo

‘The heartwood is ent from the

inner part of a redwood log —the

part that makes it resistant to

insects and decay. But there's no

natural resistance inthesapwood Color. Unlike the creamy colored

that's cut from the outer part of sapwood (top), the red heart-

wood resists insects and decay.

the log.

HEARTWOOD.'The two best

gpades of Heartwood are Clear All Heart (straight

grain, free of knots) and Heart ‘B" (some irregular

grain and a few small, tight knots), see photos be-

low. Note: We used Heart ‘B on the picnic table,

Not surprisingly, these two grades of redwood

are also the most expensive. Here in Des Moines,

Clear All Heart costs about $4.40 a board foot, and

Heart ‘B' is $3.50 a board foot,

Aless expensive graile you may want to consider

for some projects is Construction Heart/Deck

Clear All Heart, Lumber with this grade is

siraight-grained and free of knots.

Heart ‘8’. You'll see some irregular grain

‘and small knots in Heart ‘B' lumber.

Construction Heart/Deck Heart. Look for

knots of varying sizes with this grade

30 ShopNotes

Heart ($1.50 a board foot), see bottom photo. Al-

though boards in this grade aren't as straight

grained and have langer knots, you can sometimes

cut around them.

WORKABILITY. Regardless of the grade you use,

there area few things you should keep in mind when

‘working with redwood lumber. Like most other

softwoods, redwood cuts easily.

But to help reduce splintering,

it's still a good idea to first drill

pilot holes before nailing oF

serewing itn place.

‘And if there are any small

splinters along the edges, glue

them in place before sanding or

finishing as they havea tendency

to “eatch” on sandpaper, paint-

brushes, and rags,

Also, when routing redwood, it's best to sneak up

on the profile by making a number of passes to

reduce tearout and splintering.

AVAILABILITY. Becatuse redwood is such a spe-

cialty use item, you're not likely to come across it at

your local home improvement center. But you ean

find it (or order it) at many lumberyards.

If you have trouble locating redwood, you can

give the California Redwood Association a call (15-

382-0662) for the nearest dealer in your area. @

Lia)

* Outdoor Finishes

ether it's drenched in the rain or baked by

the sun, the finish on a piece of outdoor

furniture has an incredibly tough job. So it's impor-

tant to select a finish that protects the wood from.

damage caused by extremes of weather.

Inaddition, there are a couple other things I look

at before choosing an outdoor finish. How it affects

the appearance of the project for instance. And the

‘maintenance required to preserve the finish,

To strike a balance between all these things, I

‘usually select from three different types of outdoor

finishes: penetrating oil, spar varnish, or paint,

‘The easiest finish to apply isa penetrating oil that's

‘specially formulated for outdoor use. Wiping the oi

on and off (I apply at least three coats) seals out

‘moisture by penetrating inside the fibers of the wood.

Since the oil doesn’t build up on the surface, it

‘won't erack or peel. And it preserves the natural

look and feel of the wood, see photo A.

MAINTENANCE, But it doesn't take long before

an oil finish starts to look dull and loses its ability

to keep out moisture. So about every two or three

‘months, you'll need to wipe on a fresh coat.

For a more durable finish that still preserves the

natural beauty of the wood, I use an exterior (ma-

rine) spar varnish, see photo B. It forms a protec-

tive barrier against: moisture on the surface of the

‘wood. And its extremely resistant to wear,

‘FILTERS. When selecting a spar varnish, look for

one with ultra-violet (UV) filters. These filters ab-

sorb the UV rays from the sun that break down a

finish over time.

‘To take advantage ofthe filters, it's best to apply

at least three coats of spar varnish, But since the

filters gradually lose their effectiveness, you'll need

to establish a regular maintenance schedule,

‘The important thing is to renew the finish before

ft starts to deteriorate. About once a year, I sand

the finish lightly and apply another coat.

PAINT

QP hove tdes the wood good eat ofpaint sit

[provides the best protection against the weather.

That's because it keeps out moisture and pre-

vents sunlight, from penetrating the finish.

As with any finish, the end result is only as good

as what's underneath, So start by applying a heavy

‘coat of penetrating (outdoor) oil. Especially on end

grain that will wick up moisture if the paint fails.

PRIMER. When the oil dries completely (about

two or three days), the next step is to apply a good

quality alkyd (oil-based) primer. While it provides

excellent resistance to water, an alkyd paint ean

crack as the wood moves with changes in humidity.

‘TOP COATS. So when it's time to apply the top

coats, 1 use a more flexible latex (water-based)

paint, see photo C. Two coats will usually protect

the wood for several years or more.'

~< Penetrating Oil. Even

though it darkens the

wood, the most natural

ooking outdoor finish is a

penetrating oil. To ensure

continuous protection

against moisture, apply

another coat of o

every few months,

< Spar Varnish. With an

exterior spar varnish, you

get a more durable (and

{glossier) finish, Even so,

you'll need f0 maintain the

finish about once a year

10 prevent cracking

or peeling.

“Paint. Winilo it hicies

the natural beauty of the

wood, a painted finish

offers the best protection

against the weather. And

you don't have to worry

‘about renewing the

finish as frequently.

No.27 ‘ShopNotes 31

Scenes from the Shop

A The highly figured grain on this walnut scraper wood wedge and brass finger screw hold the seraper at

plane creates a fino tool that's as pleasing to look at as just the right angle to produce thin, wispy shavings.

itis to use, Like the scraper plane shown on page 4, a “And brass sole plates on the botiom resist wear.

‘A A panel full of tools is just part of the storage pro- other side as well as a back door concealed rwithin

vided by the pegboard rack shown above left and on (center). Swing out the back door and you can even.

‘page 24. Open the front door and there's storage on the hang tools on the other side of it or the wall (right)

You might also like

- ShopNotes #31 (Vol. 06) - Low Speed Grinding Jig100% (4)ShopNotes #31 (Vol. 06) - Low Speed Grinding Jig32 pages

- Shopnotes #51 (Vol. 09) - Band Saw Upgrade100% (4)Shopnotes #51 (Vol. 09) - Band Saw Upgrade32 pages

- ShopNotes #27 (Vol. 05) - Sliding Cutoff Table - TextNo ratings yetShopNotes #27 (Vol. 05) - Sliding Cutoff Table - Text32 pages

- ShopNotes #15 (Vol. 03) - Sliding Table PDF100% (2)ShopNotes #15 (Vol. 03) - Sliding Table PDF32 pages

- ShopNotes #66 - All New Table Saw Workstation100% (1)ShopNotes #66 - All New Table Saw Workstation38 pages

- Shopnotes #87 (Vol 15) - Router Table Sled PDF100% (2)Shopnotes #87 (Vol 15) - Router Table Sled PDF54 pages

- ShopNotes #60 (Vol. 10) - Aircompressor Caddy100% (2)ShopNotes #60 (Vol. 10) - Aircompressor Caddy34 pages

- Versatile Sawhorse & Lumber Storage Solutions0% (1)Versatile Sawhorse & Lumber Storage Solutions1 page

- ShopNotes #26 (Vol. 05) - Cordless Driver - Drills - Text100% (1)ShopNotes #26 (Vol. 05) - Cordless Driver - Drills - Text32 pages

- Crafts - Woodworking - Magazine - (Ebook) - Shopnotes #44 - Grinding Station100% (2)Crafts - Woodworking - Magazine - (Ebook) - Shopnotes #44 - Grinding Station32 pages

- ShopNotes #10 (Vol. 02) - Heavy Duty Lathe Stand - TextNo ratings yetShopNotes #10 (Vol. 02) - Heavy Duty Lathe Stand - Text32 pages

- ShopNotes #02 (Vol. 01) - Wooden Joiner's Mallet - Text100% (4)ShopNotes #02 (Vol. 01) - Wooden Joiner's Mallet - Text32 pages

- LIBRO MIT CURSO Inference From Data and Models (Atmospheric Science Open Course MIT 2005 231s) PDFNo ratings yetLIBRO MIT CURSO Inference From Data and Models (Atmospheric Science Open Course MIT 2005 231s) PDF231 pages

- (Ron Lenk) Practical Design of Power Supplies100% (8)(Ron Lenk) Practical Design of Power Supplies225 pages

- 6419A-En Configuring Managing Maintaining Windows Server08 Servers-TrainerWorkbook Vol2No ratings yet6419A-En Configuring Managing Maintaining Windows Server08 Servers-TrainerWorkbook Vol2190 pages

- Rotary Chuck System Parameters Setting Instructions - RLNo ratings yetRotary Chuck System Parameters Setting Instructions - RL1 page