0 calificaciones0% encontró este documento útil (0 votos)

37 vistas35 páginasPT 15

manual de servicio t7

Cargado por

manujarqueiniguezDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como PDF o lee en línea desde Scribd

0 calificaciones0% encontró este documento útil (0 votos)

37 vistas35 páginasPT 15

manual de servicio t7

Cargado por

manujarqueiniguezDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como PDF o lee en línea desde Scribd

P0112, P0113

Open circuit check

‘Batwoon intake alr temparature sensor coupler and

ECU coupler

‘brown/white-brown/white

black/blue-black/blue

Is resistance 0 02

YES

> Go to “Short circuit check".

No

a. Replace the wire hamess,

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 7, and complete the service.

No

Goto step 4.

Short circuit check

TIP

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU” on page 9-3.

Ground short circuit check “A”

Between intake alr temperature sensor coupler "1"

and ground brown/white-ground,

Lines short circuit check “B”

Trtake air temperature sensor coupler

‘brown/white-black/biue

ECU coupler “2”

‘brown/white-any other coupler terminal

black/blue-any other coupler terminal

9-62

P0112, P0113

Is resistance = 07

YES

> Goto step 4.

No

‘a. Replace the wire hamess,

. Tum the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 7, and complete the service.

No

Goto step 4,

4. Installed condition of intake air temperature sensor.

* Check for looseness or pinching.

Refer to “GENERAL CHASSIS (4)” on page 4-8.

Is check result OK?

YES

> Goto step 5.

No

a. Reinstall the sensor.

b. Tum the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

Go to step 7, and complete the service,

No

= Goto step 5.

5, Defective intake air temperature sensor.

+ Execute the diagnostic mode. (Code 05)

‘* When engine is cold: Displayed temperature is close to the ambient temperature.

‘The displayed temperature is not close to the ambient temperature + Check the intake air tem-

erature sensor.

Refer to “CHECKING THE INTAKE AIR TEMPERATURE SENSOR” on page 8-47.

Is check result OK?

YES

> Goto step 6.

NO

fa, Replace the intake air temperature sensor.

Refer to “GENERAL CHASSIS (4) on page 4-8.

b. Turn the main switch to “ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

— Go to step 7, and complete the service.

No

+ Goto step 6.

9-63

P0112, P0113

6. Malfunction in ECU.

‘* Replace the ECU, and complete the service.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

7. Delete the DTC and check that the MIL goes off.

Confirm that the DTC has a condition of “Recovered” using the YDT, and then delete the DTC.

9-64

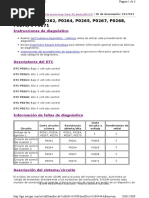

P0117, P0118

P0117, Po118

TROUBLESHOOTING

Item

[P0117] Coolant temperature sensor: ground short circuit detected.

‘* [P0118] Coolant temperature sensor: open or power short circuit detected.

Fail-safe system

‘Able to start engine

‘Able to drive vehicle

Procedure

TIP

Perform this procedure when the engine is cold.

1. Connection of coolant temperature sensor coupler.

‘* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

~ Goto step 2.

No

‘a. Connect the coupler securely or replace the sub-wire hamess.

b. Tum the main switch to “ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 8, and complete the service.

No

> Goto step 2.

2. Connection of wire harness coupler and sub-wire hamess coupler.

‘Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

Goto step 3.

No

‘a. Connect the coupler securely or replace the wire harness and/or sub-wire harness.

. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 8, and complete the service.

No

+ Goto step 3.

9-65

P0117, P0118

3. Connection of ECU coupler.

‘= Check the locking condition of the coupler.

* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

Goto step 4.

No

‘a. Connect the coupler securely or replace the wire hamess.

». Tum the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 8, and complete the service.

No

~ Goto step 4,

4, Wire hamess continuity.

Disconnect the coolant temperature sensor coupler “1”, sub-wire hamess coupler (wire hamess

side) “2”, wire harness coupler (sub-wire hamess side) "3" and ECU coupler “4”.

*Open circuit check

Between coolant femperalure sensor coupler and] green/white-green/white

sub-wire hamess coupler (wire harness side) black/blue-black/blue

Between wire hamess coupler (sub-wire harness | green/white-green/white

side) and ECU coupler Black/blue-black/blue

. =

YES

— Go to step “Short circuit check"

x

1. Replace the wire hamess and/or sub-wire harness.

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 8, and complete the service,

No

Goto step 5.

Short circuit check

9-66

P0117, P0118

1!

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU” on page 9-3.

Ground short circuit check “A”

Banneen solant temperate Sereor SOURIET"T™ Teen uhite-ground

Between wire hamess coupier (sub-wire harness .

side) “3” and ground green/white-ground

Lines short circuit check “B”

Coolant temperature sensor coupler ‘reen/white-biack/blue

‘green/white-any other coupler terminal

Black/blue-any other coupler terminal

, ‘green/white-any other coupler terminal

ECU coupler “4 lack/blue-any other coupler terminal

Wire hamess coupler (sub-wire harness side)

BA, og By, 3

P= 2 St

Is resistance = 07

YES

+ Goto step 5.

No

‘a. Replace the wire hamess and/or sub-wire harness,

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

‘YES

Goto step 8, and complete the service,

No

Goto step 5.

5. Installed condition of coolant temperature sensor.

‘Check for looseness or pinching.

Refer to “THROTTLE BODIES” on page 7-6.

Is check result OK?

YES

— Goto step 6

No

9-67

P0117, P0118

‘a. Reinstall the sensor.

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 8, and complete the service.

No

Goto step 6

6. Defective coolant temperature sensor.

‘* Execute the diagnostic mode. (Code 06)

‘+ When engine is cold: Displayed temperature is close to the ambient temperature.

‘The displayed temperature is not close to the ambient temperature —> Check the coolant tempera

ture sensor.

Refer to "CHECKING THE COOLANT TEMPERATURE SENSOR’ on page 8-45.

Is check result OK?

YES

> Goto step 7.

No

a. Replace the coolant temperature sensor.

Refer to “THROTTLE BODIES" on page 7-6.

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 8, and complete the service.

No

~ Go to step 7.

7. Malfunction in ECU.

‘* Replace the ECU, and complete the service.

Refer to "REPLACING THE ECU (engine control unit)" on page 8-38.

8. Delete the DTC and check that the MIL goes off.

‘*Confirm that the DTC has a condition of “Recovered” using the YDT, and then delete the DTC.

9-68

P0122, P0123

P0122, P0123

TROUBLESHOOTING

Item

'*[P0122] Throttle position sensor: open or ground short circuit detected.

'* [P0123] Throttle position sensor: power short circuit detected,

Fail-safe system

'*Able/Unable to start engine

‘*Able/Unable to drive vehicle

Procedure

1. Connection of throttle position sensor coupler.

* Check the locking condition of the coupler.

‘Disconnect the coupler and check the pins (bent or broken terminals and lockit

condition of the

pins).

Is the coupler condition normal?

YES

= Goto step 2.

No

‘a. Connect the coupler securely or replace the sub-wire hamess.

. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 9, and complete the service.

No

~ Go to step 2.

2. Connection of wire harness coupler and sub-wire hamess coupler.

‘* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

> Goto step 3.

NO

a. Connect the coupler securely or replace the wire harness and/or sub-wire harness.

. Turn the main switch to “ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 9, and complete the service.

No

= Goto step 3.

3. Connection of ECU coupler.

‘* Check the locking condition of the coupler.

Disconnect the coupler and check the pins (bent or broken terminals and loc!

pins).

condition of the

9-69

P0122, P0123

Is the coupler condition normal?

YES

> Goto step 4.

No

‘a. Connect the coupler securely or replace the wire hamess,

». Tum the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 9, and complete the service.

No

Goto step 4,

4, Wire hamess continuity.

Disconnect the throttle position sensor coupler “1”, sub-wire harness coupler (wire harness side)

“2”, wire hamess coupler (sub-wire harness side) “3” and ECU coupler “4”.

Open circuit check

Between throttle postion sensor coupler and sub- | baei7bive Black/Blue

wire hamess coupler (wire harness side) bh °

blue-blue

Between wire hamess coupler (sub-wire harness | Diack/biteblack/biue

side) and ECU coupler eae

(@——

@

1

Es

ee

1— 3

L,

Is resistance 0.07

YES

— Go to “Short circuit check"

No

a. Replace the wire hamess and/or sub-wire harness.

. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 9, and complete the service.

No

Goto step 5.

Short circuit check

9-70

P0122, P0123

1!

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU" on page 9-3.

Ground short circuit check “A”

Between throttle position sensor coupler 1” and] white-ground

ground blue-ground

Between wire hamess coupler (sub-wire hamess | white-ground

side) “3” and ground blue-ground)

Lines short circuit check “B”

‘Black/blue-any other coupler terminal

‘Throttle position sensor coupler white-any other coupler terminal

blue-any other coupler terminal

black/biue-any other coupler terminal

Wire harness coupler (sub-wire harness side) white-any other coupler terminal

blue-any other coupler terminal

black/blue-any other coupler terminal

ECU coupler *4’ white-any other coupler terminal

blue-any other coupler terminal

1 3

@ =

(

Q)

Is resistance = 07

YES

> Goto step 5.

NO

a. Replace the wire hamess and/or sub-wire harness.

b. Turn the main switch to “ON”, and then check the condition of the DTG using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 9, and complete the service.

NO.

+ Goto step 5.

5. Installed condition of throttle position sensor.

‘* Check for looseness or pinching.

Refer to "ADJUSTING THE THROTTLE POSITION SENSOR” on page 7-12.

Is check result OK?

YES

— Goto step 6.

No

9-71

P0122, P0123

‘a. Reinstall or adjust the sensor.

b. Turn the main switch to “ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 9, and complete the service.

No

+ Goto step 6.

6. Throttle position sensor resistance.

'* Measure the throttle position sensor resistance.

Refer to “CHECKING THE THROTTLE POSITION SENSOR’ on page 8-46.

Is check result OK?

YES

~ Goto step 7.

No

‘a. Replace the thrattle position sensor.

Refer to “ADJUSTING THE THROTTLE POSITION SENSOR” on page 7-12.

». Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

— Go to step 9, and complete the service.

No

+ Goto step 7.

7. Detective throttle position sensor.

‘* Check throttle position sensor signal.

‘+ Execute the diagnostic mode. (Code 01)

When the throttle valves are fully closed Tt

Wien throitle valves are fully open 96-106

Is check result OK?

YES

> Go to stop 8.

No

1. Replace the throttle position sensor.

Refer to “ADJUSTING THE THROTTLE POSITION SENSOR" on page 7-12

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condi

YES

Go to step 9, and complete the service.

No

~ Goto step 8.

8. Malfunction in ECU.

‘Replace the ECU, and complete the service.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

9. Delete the DTC and check that the MIL goes off.

‘Confirm that the DTC has a condition of "Recovered” using the YDT, and then delete the DTC.

9-72

n?

P0132

P0132

TROUBLESHOOTING

Item

Q, sensor: short circuit detected (power short circuit).

Fail-safe system

* Able to start engine

* Able to drive vehicle

Procedure

1. Installed condition of O, sensor.

* Check for looseness or pinching.

Refer to "ENGINE REMOVAL” on page 5-10.

Is check result OK?

YES

> Goto step 2.

No

a. Reinstall or replace the sensor.

. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

+ Go to step 2.

2. Connection of 0, sensor coupler.

‘* Check the locking condition of the coupler.

‘Disconnect the coupler and check the pins (bent or broken terminals and lockit

condition of the

pins).

Is the coupler condition normal?

YES

Goto step 3.

No

‘a. Connect the coupler securely or replace the wire harness.

b. Turn the main switch to "ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

— Go to step 7, and complete the service.

No

Goto step 3.

3. Connection of ECU coupler.

‘* Check the locking condition of the coupler.

‘Disconnect the coupler and check the pins (bent or broken terminals and loc!

pins).

condition of the

Is the coupler condition normal?

9-73

P0132

YES

= Goto step 4.

No

‘a. Connect the coupler securely or replace the wire hamess.

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

= Go to step 7, and complete the service.

No

= Goto step 4

4. Wire hamess continuity.

‘Disconnect the O> sensor coupler “1” and ECU coupler “2”.

Open circuit check

Between O, sensor coupler and ECU coupler black/blue-black/blue

gray/green-gray/green

Is resistance 0.07

YES

—>+ Go to “Short circuit check”.

No

‘a. Replace the wire hamess.

b. Turn the main switch to “ON”, and then check the condition of the DTG using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

—+ Go to step 7, and complete the service.

No

Goto step 5.

* Short circuit check

1

Disconnect the ECU related connectors before checking.

Refer to "PARTS CONNECTED TO THE ECU” on page 9-3.

‘Ground short circuit check “A”

Between 0; sensor coupler"

"and ground ‘gray/green-ground

Lines short circuit check “B”

©; sensor coupler black/blue-any other coupler terminal

gray/green-any other coupler terminal

9-74

P0132

black/biue-any other coupler terminal

ECU coupler gray/green-any other coupler terminal

Al

Is resistance ~ 0?

YES

> Goto step 5,

No

1. Replace the wire hamess,

. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

Goto step 5.

5. Defective O2 sensor.

‘Check the O, sensor.

Refer to "ENGINE REMOVAL" on page 5-10.

Is check result OK?

YES

Goto step 6.

No

‘a. Replace the Op sensor.

Refer to “ENGINE REMOVAL" on page 5-10.

bb. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

Go to step 7, and complete the service.

No

> Goto step 6.

6. Malfunction in ECU.

‘* Replace the ECU, and complete the service.

Refer to "REPLACING THE ECU (engine control unit)” on page 8-38.

7. Delete the DTC and check that the MIL goes off.

Confirm that the DTC has a condition of “Recovered” using the YDT, and then delete the DTC.

9-75

P0201

P0201

‘TROUBLESHOOTING

Item

Fuel injector #1: malfunction in fuel injector #1

Fail-safe system

“Able to start engine (depending on the number of faulty cylinders)

'*Able to drive vehicle (depending on the number of faulty cylinders)

Procedure

1. Connection of fuel injector #1 coupler.

* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

= Goto step 2.

No

‘a. Connect the coupler securely or replace the sub-wire harness.

b. Execute the diagnostic mode. (Code 36)

Is it hear operating sound?

YES

Goto step 7.

No

Goto step 2.

2. Defective fuel injector #1.

‘* Measure the fuel injector resistance.

Refer to “CHECKING THE FUEL INJECTORS" on page 8-48.

Is check result OK?

YES

— Goto step 3,

No

a. Replace the fuel injector #1

Refer to “THROTTLE BODIES” on page 7-6.

b. Execute the diagnostic mode. (Code 36)

Is it hear operating sound?

YES

— Go to step 7.

No.

Goto step

3. Connection of ECU coupler.

® Check the locking condition of the coupler.

‘Disconnect the coupler and check the pins (bent or broken terminals and locking condition ofthe

pins).

Is the coupler condition normal?

YES

9-76

P0201

= Goto step 4,

No

a. Connect the coupler securely or replace the wire hamess,

b. Execute the diagnostic mode. (Code 36)

Is it hear operating sound?

YES

= Goto step 7.

No

Goto step 4,

4. Connection of wire harness coupler and sub-wire hamess coupler.

Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

> Goto step 5,

No

‘a. Connect the coupler securely or replace the wire hamess and/or sub-wire hamess.

b. Execute the diagnostic mode. (Code 36)

Is it hear operating sound?

YES

+ Go to step 7.

No

> Goto step 5.

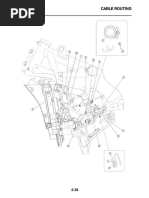

5. Wire hamess continuity.

‘Disconnect the fuel injector #1 coupler “1”, sub-wire hamess coupler (wire hamess side) “2”, wire

hamess coupler (sub-wire hamess side) “3” ECU coupler “4” and relay unit coupler “5”

Open circuit check

Between fuel injector #1 coupler and sub-wire har- | red/black-red/black

ness coupler (wire harness side) red/blue-red/blue

‘Between wire hamess coupler (sub-wire hamess

side) and relay unit coupler red/blue-red/olue

‘Between wire harness coupler (sub-wire harness

side) and ECU coupler red/black-red/black

ER SEER Spe

SLR

si

9-77

P0201

Is resistance 0.07

YES

> Go to “Short circuit check”.

No

‘a. Replace the wire hamess and/or sub-wire hamess,

b. Execute the diagnostic mode. (Code 36)

Is it hear operating sound?

YES

+ Goto step 7.

NO.

Goto step 6.

Short circuit check

TP

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU” on page 9-3.

‘Ground short circuit check “A”

+" rea/black-ground

Between fuel injector #1 coupler “1” and ground | TeX/iack groune

Between ECU coupler “4” and ground red/black-ground

Batween relay unit coupler "S" and ground red/blue-ground

Lines short circuit check “B”

Fuel injector #7 coupler red/black-red/blue

ECU coupler red/black-any other coupler terminal

Relay unit coupler red/blue-any other coupler terminal

a

TICES Ebd

Is resistance » 9?

YES

= Goto step 6.

No

‘a. Replace the wire hamess and/or sub-wire hamess,

'b. Execute the diagnostic mode. (Cade 36)

Is it hear operating sound?

YES

= Goto step 7.

9-78

P0201

No

Go to step 6.

6. Malfunction in ECU.

‘* Replace the ECU, and complete the service.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

7. Delete the DTC and check that the MIL goes off.

“Start the engine and let it idle for approximately 5 seconds.

‘* Confirm that the DTC has a condition of “Recovered” using the malfunction mode of the YDT, and

then delete the DTC.

9-79

P0202

‘TROUBLESHOOTING

Item

Fuel injector #2: maifunction in fuel injector #2,

Fail-safe system

“Able to start engine (depending on the number of faulty cylinders)

'*Able to drive vehicle (depending on the number of faulty cylinders)

Procedure

1. Connection of fuel injector #2 coupler.

* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

= Goto step 2.

No

‘a. Connect the coupler securely or replace the sub-wire harness.

b. Execute the diagnostic mode. (Code 37)

Is it hear operating sound?

YES

Goto step 7.

No

Goto step 2.

2. Defective fuel injector #2.

‘* Measure the fuel injector resistance.

Refer to "CHECKING THE FUEL INJECTORS" on page 8-48.

Is check result OK?

YES

— Goto step 3,

No

‘a. Replace the fuel injector #2.

Refer to “THROTTLE BODIES” on page 7-6.

b. Execute the diagnostic mode. (Code 37)

Is it hear operating sound?

YES

— Go to step 7.

No.

Goto step

3. Connection of ECU coupler.

® Check the locking condition of the coupler.

‘Disconnect the coupler and check the pins (bent or broken terminals and locking condition ofthe

pins).

Is the coupler condition normal?

YES

9-80

P0202

= Goto step 4,

No

a. Connect the coupler securely or replace the wire hamess,

. Execute the diagnostic mode. (Code 37)

Is it hear operating sound?

YES

= Goto step 7.

No

Goto step 4,

4. Connection of wire harness coupler and sub-wire hamess coupler.

Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

> Goto step 5,

No

‘a. Connect the coupler securely or replace the wire hamess and/or sub-wire hamess.

b. Execute the diagnostic mode. (Code 37)

Is it hear operating sound?

YES

+ Go to step 7.

No

> Goto step 5.

5. Wire hamess continuity.

‘Disconnect the fuel injector #2 coupler “1”, sub-wire hamess coupler (wire hamess side) “2”, wire

hamess coupler (sub-wire hamess side) “3", ECU coupler “4” and relay unit coupler "5"

Open circuit check

‘Between fuel injector #2 coupler and sub-wire har- | green/black-green/black

ness coupler (wire hares side) red/blue-red/biue

‘Between wire hamess coupler (sub-wire hamess

side) and relay unit coupler rea/blue-red/olue

Between wire hamess coupler (ub-wire harmess

side) and ECU coupler Steenihlacie qreen/bieci:

@

9-81

P0202

Is resistance 0.07

YES

> Go to “Short circuit check”.

No

‘a. Replace the wire hamess and/or sub-wire hamess,

b. Execute the diagnostic mode. (Code 37)

Is it hear operating sound?

YES

+ Goto step 7.

NO.

Goto step 6.

Short circuit check

TP

Disconnect the ECU related connectors before checking.

Refer to "PARTS CONNECTED TO THE ECU’ on page 9-3.

‘Ground short circuit check “A”

Between fuel injector #2 coupler “1” and ground | 2Yeen/black« ground

7 Fed/blue-ground

Between ECU coupler "4" and ground green/black-ground

Batween relay unit coupler "S" and ground red/olue-ground

Lines short circuit check *B”

Fusl injector #2 coupler Green/black-red/biue

ECU coupler Goto step 3.

NO

‘a. Connect the coupler securely or replace the wire harness.

. Grank the engine, and then check the condition of the DTC using the malfunction mode of the

Yor.

Is it in the “Recovered” condition?

YES

= Go to step 7, and complete the service.

No

> Goto step 3.

3. Wire hamess continuity.

‘Disconnect the crankshaft position sensor coupler “1” and ECU coupler “2”.

Open circuit check

‘Between crankshaft position sensor coupler and | black/biue-biacl/blue

ECU coupler gray-gray

9-84

Is resistance 0.07

YES

> Go to “Short circuit check”.

No

‘a. Replace the wire hamess.

. Crank the engine, and then check the condition of the DTC using the malfunction mode of the

YOT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

+ Goto step 4.

Short circuit check

TIP

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU" on page 9-3.

Ground short circuit check “A”

and ground gray-ground

Lines short circuit check “B”

ap" black/blue-any other coupler terminal

ECU coupler “2 gray—any other coupler terminal

al

1 1

Is resistance = 07

YES

> Goto step 4.

No

9-85

‘a. Replace the wire hamess.

b. Crank the engine, and then check the condition of the DTC using the matfunction mode of the

yor.

Is it in the “Recovered” condition?

YES

= Go to step 7, and complete the service.

No

> Goto step 4.

4. Installed condition of crankshaft position sensor.

‘* Check for looseness or pinching.

‘* Check the gap (0.85 mm (0.03 in)) between the crankshaft position sensor and the generator rotor.

Is check result OK?

YES

> Goto step 5.

No

‘a. Reinstall or replace the sensor.

b. Crank the engine, and then check the condition of the DTC using the malfunction mode of the

Yor.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

= Goto step 5.

5. Defective crankshaft position sensor.

* Check the crankshatt position sensor.

Refer to “CHECKING THE CRANKSHAFT POSITION SENSOR’ on page 8-42.

Is check result OK?

YES

Goto step 6.

No

‘a. Replace the crankshaft position sensor.

. Crank the engine, and then check the condition of the DTC using the maifunction mode of the

Yor.

Is it in the “Recovered” condition?

YES

Go to step 7, and complete the service.

No

Goto step 6.

6. Malfunction in ECU.

‘+ Replace the ECU, and complete the service.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

7. Delete the DTC and check that the MIL goes off.

‘* Confirm that the DTC has a condition of “Recovered” using the YDT, and then delete the DTC.

9-86

P0351

P0351

TROUBLESHOOTING

Item:

Cylinder-#1 ignition coil: open or short circuit detected in the primary lead of the cylinder-# ignition

coil.

Fail-safe system

*Unable to start engine

*Unable to drive vehicle

Procedure

1. Connection of cylinder-#1 ignition coil coupler.

* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

= Goto step 2.

No

‘a. Connect the coupler securely or replace the wire hamess,

b. Start the engine and let it idle for approximately 5 seconds.

‘c. Check the condition of the DTC using the matfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

= Goto step 2

2. Connection of ECU coupler.

‘* Check the locking condition of the coupler.

‘= Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

> Goto step 3,

No

‘a. Connect the coupler securely or replace the wire hamess.

b. Start the engine and let it idle for approximately 5 seconds.

‘e. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

Goto step 3.

3. Wire hamess continuity.

* Disconnect the cylinder-#1 ignition coil coupler “1”,

coupler “3”,

* Open circuit check

ECU coupler “2” and handlebar switch (ight)

9-87

P0351

Betwoan cylinder Ignition col coupler and ECU

eave orange-orange

Betvvesn oylinder-#1 Ignition col coupler and han

See rat rind captor red/black-red/black

isle Rene oh,

eben a

Is resistance 0 07

YES

> Go to “Short circuit check”.

No

a. Replace the wire hamess.

b. Start the engine and let it idle for approximately 5 seconds.

©. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

= Goto step 4.

Short circuit check

TP

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU" on page 9-3.

Ground short circuit check “A”

Between cylinder-#1 ignition coil coupler “1” and | orange-ground

ground red/black-ground

Lines short circuit check “B”

ylinder-#1 ignition coil coupler ‘orange-red/black

ECU coupler “2” ‘orange-any other coupler terminal

Handlebar switch (ight) coupler “3 red/black-any other coupler terminal

9-88

P0351

Is resistance » 07

YES

> Goto step 4,

No

‘a. Replace the wire harness,

b. Start the engine and let it idle for approximately 5 seconds.

‘c. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

= Goto step 7, and complete the service.

No

Goto step 4.

4, Installed condition of oylinder-#1 ignition coll.

‘* Check for looseness or pinching.

Is check result OK?

YES

— Goto step 5.

No

‘a. Reinstall or replace the ignition col

b. Start the engine and let it idle for approximately 5 seconds.

‘c. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Goto step 7, and complete the service.

No

Goto step 5.

5. Defective cylinder-#1 ignition coil,

‘* Measure the primary coil resistance of the oylinder-#1 ignition coil.

Refer to “CHECKING THE IGNITION COILS” on page 8-41.

Is check result OK?

YES

> Goto step 6.

No

a. Replace the cylinder-#1 ignition coil

Refer to “CAMSHAFTS" on page 5-20.

b. Start the engine and let It idle for approximately 5 seconds.

©. Check the condition of the DTC using the malfunction mode of the YOT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

= Goto step 6.

6. Malfunction in ECU.

‘* Execute the diagnostic mode. (Code 30)

Confirm that spark plug does not sparking.

9-89

P0351

‘* Replace the ECU, and complete the service.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

7. Delete the DTC and check that the MIL goes off.

Confirm that the DTC has a condition of “Recovered” using the YDT, and then delete the DTC.

9-90

P0352

TROUBLESHOOTING

Item

Cylinder-#2 ignition coil: open or short circuit detected in the primary lead of the cylinder-#2 ignition

coll.

Fail-safe system

'*Unable to start engine

+ Unable to drive vehicle

Procedure

1. Connection of cylinder-#2 ignition coil coupler.

* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

= Goto step 2.

No

‘a. Connect the coupler securely or replace the wire hamess,

b. Start the engine and let it idle for approximately 5 seconds.

‘c. Check the condition of the DTC using the matfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

Goto step 2

2. Connection of ECU coupler.

‘* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

> Goto step 3,

No

‘a. Connect the coupler securely or replace the wire hamess.

b. Start the engine and let it idle for approximately 5 seconds.

‘e. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

Goto step 3.

3. Wire hamess continuity.

‘Disconnect the cylinder-#2 ignition coil coupler “1”,

coupler “3”,

* Open circuit check

ECU coupler “2” and handlebar switch (ight)

9-91

Between cylinder Wa ignition col coupler and ECU

coupler Go to “Short circuit check”.

No

a. Replace the wire hamess.

b. Start the engine and let it idle for approximately 5 seconds.

©. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

= Goto step 4.

Short circuit check

TP

Disconnect the ECU related connectors before checking.

Refer to “PARTS CONNECTED TO THE ECU" on page 9-3.

Ground short circuit check “A”

Between cylinder-#2 ignition coil coupler “1” and | gray/red-ground

ground red/black-ground

Lines short circuit check “B”

Cylinder-#2 ignition coil coupler ‘gray/red-red/black

ECU coupler “2” ‘gray/red-any other coupler terminal

Handlebar switch (ight) coupler “3 red/black-any other coupler terminal

9-92

Is resistance » 07

YES

> Goto step 4,

No

‘a. Replace the wire harness,

b. Start the engine and let it idle for approximately 5 seconds.

‘c. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

= Goto step 7, and complete the service.

No

Goto step 4.

4. Installed condition of cylinder-#2 ignition coll.

‘* Check for looseness or pinching.

Is check result OK?

YES

— Goto step 5.

No

‘a. Reinstall or replace the ignition col

b. Start the engine and let it idle for approximately 5 seconds.

‘c. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Goto step 7, and complete the service.

No

Goto step 5.

5. Defective cylinder-#2 ignition coil,

‘* Measure the primary coil resistance of the cylinder-#2 ignition coil.

Refer to “CHECKING THE IGNITION COILS” on page 8-41.

Is check result OK?

YES

> Goto step 6.

No

a. Replace the cylinder-#2 ignition coil

Refer to “CAMSHAFTS" on page 5-20.

b. Start the engine and let It idle for approximately 5 seconds.

©. Check the condition of the DTC using the malfunction mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

= Goto step 6.

6. Malfunction in ECU.

‘* Execute the diagnostic mode. (Code 31)

Confirm that spark plug does not sparking.

9-93

‘* Replace the ECU, and complete the service.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

7. Delete the DTC and check that the MIL goes off.

Confirm that the DTC has a condition of “Recovered” using the YDT, and then delete the DTC.

9-94

P0458

TROUBLESHOOTING

Item

Purge cut valve solenoid: open circuit detected.

Fail-safe system

“Able to start engine

Able to drive vehicle

Procedure

1. Connection of purge cut valve solenoid coupler.

* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

= Goto step 2.

No

‘a. Connect the coupler securely or replace the wire harness,

b. Turn the main switch to “ON”, and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

~ Go to step 7, and complete the service.

No

+ Goto step 2.

2. Connection of ECU coupler.

‘* Check the locking condition of the coupler.

‘* Disconnect the coupler and check the pins (bent or broken terminals and locking condition of the

pins).

Is the coupler condition normal?

YES

> Goto step 3.

NO

‘a. Connect the coupler securely or replace the wire hamess.

. Turn the main switch to "ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

+ Goto step 3.

3. Wire hamess continuity.

‘Disconnect the ignition fuse “1”, purge cut valve solenoid coupler

switch coupler “4”

* Open circuit check

ECM coupler “3” and main

9-95

Between ignition fuse holder and purge cut valve

solenoid coupler

red/white-red/white

Between purge cut valve solenoid couplerand ECU

coupler

browr/red-brown/red

‘Between main switch coupler and ignition fuse

holder

browrvblue-brown/blue

Is resistance 0 07

YES

> Go to “Short circuit check”.

No

a. Replace the wire hamess.

b. Turn the main switch to “ON", and then check the condition of the DTC using the malfunction

mode of the YDT.

Is it in the “Recovered” condition?

YES

+ Go to step 7, and complete the service.

No

Goto step 4.

Short circuit check

TIP.

Disconnect the ECU related connectors before checking.

Refer to “REPLACING THE ECU (engine control unit)” on page 8-38.

Ground short circuit check “A”

Between purge cut valve solenoid coupler "2" and_| red/white-ground

ground brown/red-ground

Between main switch coupler “4” and ground ‘rown/blue-ground

Lines short circuit check “B"

Purge cut valve solenoid coupler Tediwhite-brownired

ECU coupler “3 ‘brown/red-any other coupler terminal

‘Main switch coupler brown/blue-red

9-96

También podría gustarte

- Isuzu D-Max 3.0 L Diesel TF 4ja1-Tc - TF 4jh1-Tc - nkr4jh1-Tc - Service Manual (100-250)Aún no hay calificacionesIsuzu D-Max 3.0 L Diesel TF 4ja1-Tc - TF 4jh1-Tc - nkr4jh1-Tc - Service Manual (100-250)151 páginas

- Suzuki Gran Nomade RHZ (060-100) Anali (01-20) .En - Es0% (1)Suzuki Gran Nomade RHZ (060-100) Anali (01-20) .En - Es20 páginas

- Diagnóstico del Sistema de Control del MotorAún no hay calificacionesDiagnóstico del Sistema de Control del Motor16 páginas

- Diagnóstico de Falla P1915 en Chevrolet Colorado 2010Aún no hay calificacionesDiagnóstico de Falla P1915 en Chevrolet Colorado 201014 páginas

- Diagnóstico DTC P0563 en vehículosAún no hay calificacionesDiagnóstico DTC P0563 en vehículos4 páginas

- Manual de Mecánico - VOLUMEN 3 - Honda Accord 1991Aún no hay calificacionesManual de Mecánico - VOLUMEN 3 - Honda Accord 1991150 páginas

- Diagnóstico DTC P0101 para Nissan SentraAún no hay calificacionesDiagnóstico DTC P0101 para Nissan Sentra10 páginas

- Diagnóstico DTC P0563: Procedimiento y PasosAún no hay calificacionesDiagnóstico DTC P0563: Procedimiento y Pasos2 páginas

- Comprobación Sensor de Posición de Marcha Engranada Nissan Navara D40 Yd25deAún no hay calificacionesComprobación Sensor de Posición de Marcha Engranada Nissan Navara D40 Yd25de6 páginas

- Diagnóstico del Sistema FI Yamaha Fazer 250Aún no hay calificacionesDiagnóstico del Sistema FI Yamaha Fazer 25071 páginas

- Diagnóstico DTC P0138 para VehículosAún no hay calificacionesDiagnóstico DTC P0138 para Vehículos3 páginas

- Diagnóstico DTC P0135: Procedimiento Paso a PasoAún no hay calificacionesDiagnóstico DTC P0135: Procedimiento Paso a Paso2 páginas

- DTC P0261, P0262, P0264, P0265, P0267, P0268, P0270, o P0271100% (1)DTC P0261, P0262, P0264, P0265, P0267, P0268, P0270, o P02713 páginas

- 2013 Jeep Patriot P2101-Rendimiento Del Motor de Control Electrónico Del Acelerador 3Aún no hay calificaciones2013 Jeep Patriot P2101-Rendimiento Del Motor de Control Electrónico Del Acelerador 36 páginas

- Diagnóstico Motor SQR477F y Códigos DTCAún no hay calificacionesDiagnóstico Motor SQR477F y Códigos DTC65 páginas

- Ford 97 Duty p0344 Prueba Del Circuito CamAún no hay calificacionesFord 97 Duty p0344 Prueba Del Circuito Cam3 páginas

- Contenido de Reparación para Mazda CX-7 2010Aún no hay calificacionesContenido de Reparación para Mazda CX-7 20104 páginas

- Diagnóstico de Transmisión Honda FitAún no hay calificacionesDiagnóstico de Transmisión Honda Fit338 páginas

- Manual de Diagnóstico Sunray 2.7 Cti - 123501Aún no hay calificacionesManual de Diagnóstico Sunray 2.7 Cti - 12350124 páginas

- Manual de Mecánico - VOLUMEN 2 - Honda Accord 1991Aún no hay calificacionesManual de Mecánico - VOLUMEN 2 - Honda Accord 1991150 páginas

- Diagnóstico DTC P1491 EGR Honda AccordAún no hay calificacionesDiagnóstico DTC P1491 EGR Honda Accord6 páginas

- Diagnóstico DTC P0198: Sensor EOT AltoAún no hay calificacionesDiagnóstico DTC P0198: Sensor EOT Alto7 páginas

- 138-Service-Manual-Honde-Nc700 (176-186) (1) .En - EsAún no hay calificaciones138-Service-Manual-Honde-Nc700 (176-186) (1) .En - Es11 páginas

- 2017-2023 CR-V Diagnóstico de Fallas Por DTC - P0045Aún no hay calificaciones2017-2023 CR-V Diagnóstico de Fallas Por DTC - P00456 páginas

- Gsi Showdoc - Do Docsyskey 1920054& CelAún no hay calificacionesGsi Showdoc - Do Docsyskey 1920054& Cel3 páginas