0% encontró este documento útil (0 votos)

85 vistas21 páginasFormato WPS para Soldadura en Excel

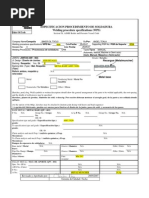

Este documento proporciona un formato sugerido para especificaciones de procedimientos de soldadura (WPS) que incluye secciones para detalles de la junta, metales base y rellenos, posiciones, precalentamiento, características eléctricas y técnica. También proporciona un formato sugerido para registros de calificación de procedimientos (PQR) que incluye secciones para detalles de la junta, metales base y rellenos, posiciones, precalentamiento, características eléctricas

Cargado por

Roberto GarciaDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como XLS, PDF, TXT o lee en línea desde Scribd

0% encontró este documento útil (0 votos)

85 vistas21 páginasFormato WPS para Soldadura en Excel

Este documento proporciona un formato sugerido para especificaciones de procedimientos de soldadura (WPS) que incluye secciones para detalles de la junta, metales base y rellenos, posiciones, precalentamiento, características eléctricas y técnica. También proporciona un formato sugerido para registros de calificación de procedimientos (PQR) que incluye secciones para detalles de la junta, metales base y rellenos, posiciones, precalentamiento, características eléctricas

Cargado por

Roberto GarciaDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como XLS, PDF, TXT o lee en línea desde Scribd