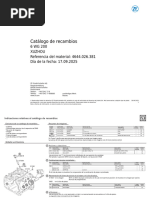

100%(1)100% encontró este documento útil (1 voto)

1K vistas24 páginasTransmision 8JS118TB B

manual de servicio

Cargado por

Fredy VelazquezDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como PDF o lee en línea desde Scribd

100%(1)100% encontró este documento útil (1 voto)

1K vistas24 páginasTransmision 8JS118TB B

manual de servicio

Cargado por

Fredy VelazquezDerechos de autor

© © All Rights Reserved

Nos tomamos en serio los derechos de los contenidos. Si sospechas que se trata de tu contenido, reclámalo aquí.

Formatos disponibles

Descarga como PDF o lee en línea desde Scribd

8JS118TB-B

OPERATION MANUAL

SHAANXI FAST AUTO DRIVE GROUP CO., LTD.

SHAANXI FAST GEAR CO., LTD.

PREFACE

Fast twin-countershatt transmission manufactured by Shaanxi Fast Auto Drive Group

Co, Ltd, introduced from USA, is the world advanced-level high-power, multi-

speed, mechanical transmission. It adopts combination design of Main-case and

‘Aux- case, with Twin Countershaft Driving, with the mainshaft and mainshaft gear are

in a floating condition, and the friction cone of synchronizer adopts the nonmetal

friction material with high performance. Fast Transmission series is an ideal

transmission for heavy-duty vehiole in current age. Shaanxi Fast Auto Drive Group Co.,

Ltd. now manufactures the following twin-countershaft transmissions in batch

production: AT-11609A, RT-11509C, RTO11609E, RTO-11509F, 7DS90, 7DS100,

708118, 7JS100, 8JS100, 8/S118, BS1OOT-B, 8/ST18T-B, B/S130T-B, 9S119,

9US119T-B, 9J8195, 9J8135T-B, 9/5150, 9JS150T-B 9/8160, 948220, 12/8160T,

1281807, 12J8200T, 16JS180T, 16JS200T, 16/S240 ete

8JS118TB-B transmission is a kind of new synchronized transmission designed and

manufactured by Shaanxi Fast Auto Drive Group Co., Lid itself ater 8JS130T

transmission. it adopts the successful experience of 8JS130T transmission, and

‘optimized the gears, and forms a new kind of transmission with new torque and ratios

to meet the market demands.

The text aims at introducing operation principles, typical structure and precautions of

8)51187B-8 twin-countershatt fully-synchronized transmission to our customers and

Obs.

‘Shaanxi Fast Auto Drive Group Co., Ltd. can re-design, refit, maintenance and serve

and supply spare parts upon user's requirements.

To provide the customers with satisfactory product and service is the purpose of

Shaanxi Fast Auto Drive Group Co., Ltd, We welcome the vast numbers of customers

to our plant for business contacting and serve you wholeheartedly.

1. Main performance parameters and coding regulations of

8JS118TB-B transmission

"Transmission model Rated Input Power Rated input Torque Rated Rotation Speed

aisi18T8-8 220K +180Nm 2600p os

Spend alos aie

a Low-speed Secon —__—ig-speed Section Capacity. giaht

Roh Ala ET 8D

eUSti6TE-8 11.95 1140 794 563 406 281 196 139 1.00 13 267

ais B

Code of Spaed Ratio

——— Fully-synchronized

Mechanical Control

Twin-countershatt

put Torque }—>

a>} CO =

ac ae

a =

6-4 =

1+ ee

3 -—___— >

Figure 2 Power Transfer Path

| (staan Fast Gent Co, Li

4. Typical structure of 8JS118TB-B transmission

1) Twin-countershaft structure

The Main and Aux Case of 8JS118TB-8 transmission are all adopt two countershafts with same

structure, alternate with180°,the power is input from input shat, and then it can be distributed

to the two countershafs nally inttux tothe Counter shaft for output, so isthe Aux Case.

‘As theoretically each countershatt can only transfer 1/2 torque, so using the twin-countershaft

can reduce the center distance of transmission, the width of gears is less, axial size is shorter

and weight is lower. After using two countershafts, ears of each speed on main shaft must be

mesh with two gears on Counter shatt at the same time.

For meeting the correct meshing and distributing the load evenly, the gears of main shaft in

radial toating status on main shaft. The main shat adopts the floating structure with hinge jin

as figure 3. The front-neck of main shaft insert into the hole of Input Shaft, the gulde steve with

ail is pressed into hole, there is enough radial clearance between the neck of main shaft and

Guide Sleeve. The back end of main shaft insert into inner hole of Drive Gear in Aux Case by

Involute spine, the shaft neck of Drive Gear in Aux. Case is supported on hole of the ball

bearing

1. Main sett 2. Input Shaft 3. npot Stat Gear 4 Drive Ger, an Case

Figure 3 Floating Structure of Main shaft

Shaan Fast Gear Co, Lid.

Owing to Gears of each speed main shaft in floating state on main shaft, thus traditional roller

bearing is canceled. When working, te force from two Countershaft Gears stress to main shaft

Gears are equal in intensity, therefore they wil counteract each other, at this moment the main

staft is only bearing the torque, but not bearing flexural torque, so the stress condition on main

siaft and bearing is improved, and the reliability and durabity of transmission are improved

realy

2) Timing and timing process

In order to solving the correct meshed between the gears of twin countershaft and gears of

‘main shaft, so. “Timing” must be carted on

“Timing” means when assembly transmission, inserting the marked teeth of dlving gears an

Countershafts into the marked groove of two group teeth on input shaft (each group include two

adjacent teeth), as figure 4

Timing for Aue. case should be carried on as above-mentioned method. Usually choose the rear

pair of gears to do the timing

Process of “timing” +

(1) Mark on any two adjacent teeth of gear of input shaft then mark on its symmetrical teath on

the other side, Teeth between the group of marks shouid be equal

1. Gear, Lett Countershatt 2 Inout Stat Gear 3. Gear, ight Countestat

Figure 4 Timing for Transmission Assembling

(2) In order to recognize, mark on tooth of every drive gear of the countershaft that dead

against the gear groove.

(3) When assembiy, insert the two marked teeth the countershaft gear nto the clearance of the

marked teath on two sides ofthe input shat gear.

To be convenient for “timing” , al the gears inthe transmission are straight teeth gears, and

the teeth numbers of gears onthe input shaft, main shaft and main shaft auxiary case are with

‘even number

3) Shifting mechanism

‘The 1,2,34.5.6,7.8 speeds in the main case of 8/S11878-B transmission are installed with new=

type doubla-cone-taced lock-ting synchronizer, and the reverse speed is engaged by sliding

sleeve. See figure 5, structure ilustration of double-cone-facedlock-ring syncnronzer.

687149

ti

1. engaging tet of synchronizer 2. inner can af schronizer 9, taper body of synchronizer

4: outer cone of synchronizer 5. sting otc of syctronier 6 locating book

7. sling book 8. Spring 9.syncvonies hub

Figure 5 synchronizer assembly

The lock ring synchronizer is adopted widely currently because it has compact structure, good

performance, high relabilty and low cost. The only shortage is that the friction torque of

Synchronizer is. smaller. Twin-cone-faced lockring synchronizer Is 2 newly designed

synchronizer device, based on similar working principle and structure with the locking

synchronizer. It inherits the advantages of the lock-ring synchronizer and makes up the

shortage by improving the fiction torque of synchronizer.

‘There isa lock-in inertial synchronizer in the auxiliary section of BJS118TB-8 transmissions. It

is controled by the shitting cylinder of auxiliary section of transmission and it has action only

when converting from high speed section to low speed section or fram low speed section to

high speed section. ts action is controlled jointly by the horizontal shifng lever and commuting

air valve. See figure 6, structure ilustration the synchronize.

5. high riction tape 2. high synarontcing rng 3. siting sleeve 4 low ction tape

5. lak-pn, low speed 6 cane ng low speed

7. ek, highspeed 8. Spring

Figure 6 Synchronizer in aux. Section

—¢ Shaanxi Fast Gear Co, Led

‘There are three lock pin 5 and 7 that are separately riveted on te high synchronizing cing 2 and

low synchronizing rng 6, ad sliding sleeve 3 ls connected with aux. output shat through spline

The high synchronizing ring and low synchronizing ring are sintered by powder metallurgy and

coated with high-performance non-metal material 1 and 4 on the Inner cone of high

‘synchronizing ring and outer cone of low synchronizing ring, with high friction coefficiency and

long lifespan. There are corresponding outer cone and inner cone on the drive gear and main

shaft reduction gear of aux. Section.

4) Control mechanism

There are two kinds of control mechanisms for 881 18TB-B transmission, that are dlrect

control (single H) and remote conirol single H or double H).

(1) Direct control (single H)

Figure 7 is the air path of single H control mechanism. Compressed air comes into the

Converting ar valve 4 through air itrating adjustor 8, and connects high speed or low speed by

the pre-selecting valve 1 inthe contro hand bal

Compressed air inlet

0.7-0.80Fa,

1. pre-soocting vale (control hand bal) 2. ranging speed ovine

3 alr ftating adjuster 4. Converting ar valve

Figure 7 Air path illustration of single H control mechanism

ee eee ea

Figure 8 is the control band ball position of direct (single H) control mechanism

Figure 8 Control band ball position of single H control mecha

(2) Remote control mechanism

8S118TB-8 transmission has two kinds of remote control methods, thet are single lever

‘ouble-H and double lever double-H. Main section of the transmission is controlled by hand,

‘and the control band ball position see figure 9. Inthe double H mechanism, 1-2-3-4 and reverse

speeds are in high speed section and §-6-7-8 speeds are in high speed section. The

‘transmission has two neutral postions, one is atthe neutral speed of 3-4 speed in low speed

‘ection and the other oneis atthe neutral speed of S-Bspeed in high speed section

BZ

Figure 9 Control band ball position of double H control mechanism

‘Aux. section of the transmission is controlled by air, and the air pressure while shifting is

0.41-0.440Mpa See figure 10 air path of double H shitting mechanism.

‘The block on the horizontal shifting lever of double H control device controls the double H valve

directy, and connects the alr path of high speed section or low speed section to realize

automatic converting of high speed and low speed. Hole 1 on the double H valve isthe ar inet,

hole 2 and 4 are air outlet, hole 8 and 6 are ar exhausting opening,

(+ shoansi Fast Gear Co,, Lid

Compressed aint

[estate

1. Double ar-vabe 2Ranging eylnser air ftrating aust

Figure 10 Air path of double H shifting mechanism

5) Double H control device

{2) Single lever double H control device

See figure 11. The single lever double H control mechanism is made up of operation device

housing, double H air valve, outer shifting arm, horizontal shifting lever, reverse switch control

back, shitting block, balancing spring(2 pcs), locating ring, locating column plug(2 pcs) .

compressed soring(2 pcs), vent plug, indicator switch, stating pin and so on. It is used for

selecting, engaging and disengaging a speed

Outer shitting arm, reverse switch control block, shifting block and locating ring are equipped

‘on the horizontal shifting lever. By moving or rotting the horizontal shifting lever through

‘operating the outer shifting arm process selecting. engaging and disengaging a speed,

Part ofthe shifting block is designed fan-shaped, and edge of the fan is designed to be a 30°

bevel. When the horizontal siting lever Is moving to high-speed section, the spherical siding

column of double-H ar valve will draw back smoothly, so high-speed air path of double H air

valve will be open; when the horizontal shiting lever is moving to low-speed section, the valve

disk of double H air valve willbe popped up by spring force, so low-speed air path willbe open.

Two ends of the location ring flange are designed to be the same angle with location column

cone, effected by the balance spring of horizontal shitting lever, radial location column plug

and compressed spring the horizontal shifting lever keeps locating at Sth /6th neutral in high

speed section and at 3rd/4th neutral in the low-speed section when engaging neutal speed, so

itis convenient fora driver to operate

(b) Double lever double H control device

See figure 12, double lever double H control device. The inner structure of it is similar to the

single lever double-H operation device. The only difference Is that selecting 2 speed and

‘engaging or disengaging a speed are realized by two different pats. Rotating the selecting

‘connector can realize selecting a speed, and rotating the shifting arm can realize engaging or

disengaging a speed.

cdleco

1, Dusiroo cover 2 Oi seal 3. double H devcw operation housing 4. Reverse switch contr bik F

‘Shing bar € Honzontat siting lever 7.10, Balance spring Location column plug 8. Location ring

11. Sie pate 12. Compressed spring 13, Double Har va 14. Vat plug 15. Outer siting am

Figure 11 Single

er double H device

#shaanxi Fast Gear Co,, Ltd

' [oe

1.3Balnce spring 2.Location ring 4.Shiting bar 6 Double control devi housing

‘Horizontal siting lever 7. Reverse indicator ight Neutra incair gt

9 Parton 10.0utershiting arm 11 Siting connector 12.Spine sieve

18 Reverse sich contol block 14.8er 15.Tutn Hair valo 16.Compressed spring

17 Location column plug 18.Side pate 19.Window cover 20.hiing connector

Figure 12 Double lever double H control device

tt

6) PTO

To meet the equrements of some special vehicles, JSt18T8-8 Transmission has two kinds of

TOs, tha are front PTO and rear PTO. Powe akingot rom the lngthened Countershat of

the Aux cas, it scaled. “tear PTO" “Rear PTO Is common used. Power taking-t

between the clutch nosing and ansmisson i caled “iront PTO” or “Ful PTO™

\When the rear PTO applied, the Aux Case must be engaged the neutral position for the purpose

Of stop and power taking-off. Owing to Aux Case controlled by ar, there is no neutral po:

To deal with this problem, itis simple to remove the cover of Aux Case cylinder and add 2

neutral positon cylinder. Structure of neutral position cylinder is shown in figure 13, and the

Indicated location is neutral postion. Following is a brief introduction of power taking-off

Drocess of 8/81 18TB-B transmission

Operation instruction of 8/S118TB-8 transmission with rear PTO,

* Taking-off power when the vehicle is running (take PTO QH50 as example):

a) Firstly drive slowly and put the transmission at low-speed section

} Put the operating ever of transmission at neutral position

©) As in figure 14, get through hole b of PTO, lt the PTO engaged

4) Engage the transmission at required gear, andthe PTO will work as the vehicle maving on

= Taking-off power when the vehicle stops

a) Firstly put the operating lever at high-speed section

) Get through hole c

©) Put the operating laver at low-speed section

4) Asin figure 14, get through hole b of PTO, let the PTO engaged

«) Engage the transmission at required gear, and the PTO wil work as the vehicle moving on.

Notice: Operating the PTO must strictly accord the operation criterion, otherwise

‘may destroy the synchronizer Aux. Case in short period.

s 1.Rang fork shat

= 2 2 Range Oyinder

5 Rear cover

7 2 4 Rang Cynder Pston

a 5O-Ring

ae 5 6 Location Ring

7.0-Ring

2B Hex tylon Look mit

2 Neutral Postion Cylinder

10. Buide Pn

11 Cylinder Piston for Neural

Psion

12.0-Ring 13. 0-Ring

Figure 13 Structure Drawing of normal Neutral Position Cylinder

‘Shaanxi Fast Gear Co., Lid

Dismantie and assembly of 8JS118TB-8 see ¢ Fuller Twin Gountershaft Transmission

Maintenance Manual authorized by SAGGW.

6. Operating and maintaining of 8J8118TB-B

twin-countershaft Transmission

Proper and corretion operating and maintaining transmission is vary important for vehicle's

safety and reliability and also the working life ofthe transmission, following shoulé be well

observed

1) Brand of the gear oil

Transmission should be filed with high quality ger ol, and the performance ofthe cil should

be not less than B5W/90,

2) Correct oil level

No No Yes

Figure 15 Oil level

The oil level should be inspected by conic filing-hole on the side of case, and the cil level

should be even with the lower edge of the oll-ling arfice, Over-‘tiling vill cause oll

temperature increase or ol leakage; underfiling wil cause bad lubrication of pars, even burn

of transmission

3) Oil changing cycle

New Transmission should change ubicaing oi after running 2000-5000 km.

(Check lubricating oll level and leakage after running each 10000 Km, make up at any time.

Chango lubricating oi after running each 60,000 Kn,

4) Working Temperature

‘The lubrication oil temperature can not above 120°C and bellow -40'C: in @ continuous work

Period. ifthe temperature above 120°C, the lubrication oll will decompound and life of the

transmission will be shortened

5) Angle of inclination when working

Ifthe angle of inclination of transmission exceeds 12° when working, there will not be enough

lubrication, So a lubrication pump or cooling device should be installed on the transmission to

‘uarantee good lubrication. (Angle of Incination equals to transmission installation angle on the

chassis adding the ange of slop.)

6) Towing and sliding

‘When the transmission is the working, continuous rotation of gears and shafts can provide

enough lubricating ol for transmission, When the rear wheels of the vehicle is being towed,

ountershaft gears and main shaft gears of the main case don't rotate, but the main shaft driven

by the rear wheels rotate at high speed, which wil destroy the transmission badly

‘To prevent the bad consequence, the below should be followed:

Don't neutral slide when the engine is going out

‘Don't neutral slide when the clutch pedals stepped down.

| the vehicle needs towing, you can draw out the hal shaft or off the crve shaft, or tow with the

Arve shaft pat from the earth

-*Shaanxi Fast Gear Co., Ltd,

Warnings

1. Before shifting, clutch shouldbe rleasd entirely. Siting lever should be pushed to make

sliding clutch totally in engagement.

2, Shifting lever has neutral postions that are at 5*--6° neutral postion at high-speed section

‘and 3-4" neutral position at low-speed section. When stopping the vehicle, transmission

should be set at low-speed position

3. When engaging a reverse, frst do stop the veicl, then engage, so as to prevent breaking the

Spare parts inside the trensmission. When engaging @ reverse, use bigger force to choose the

speed to overcome the resistance ofthe reverse lock

4, Regularity Check air vent-plug, if blocked with dirt, should be cleaning at any moment.

5. Should check filter trap of air fitrating adjustor each running 20,000 Km, cleaning fiter trap

‘and wall of ftrating adjustor with subs, and make it dry with compressed ar.

6. When change from high to low speed (or from low to high), don't skip spaed, otherwise life

(of synchronizer in Aux case wil be shortened.

7. Forbidden to change from high to low (or from low to high), when vehicle downhill

8. Adopt 1st speed or 2 speed to start, acvording to highway condition.

8, Before vehicle’ starting, brake should be released. If your automobile adopts the pneumatic

brake, only after turning on brake valve and waiting unt air pressure going up to required

Pressure, you can engage a speed for starting

101f there Is abnormal noise, you fll heavy in operation, stop and chack immediately,

11.Dontt dismantie or assembly a transmission by yourself during the “three guerantee”

period.

7. Spare parts list of 8JS118TB-B transmission

No. Part Number

1 JSt30T-1701010

2 AATe9

3 8674

4 sadsteoT-1701025

5 JSt18TB-17011008

6 Jstisr-17010478

7 Jst00-1701080

8 ust30T-17020108

9 A-cOs001

10 J8118-1707010

11 asCogoo2

12” 8677

1318410

14 19668

151684

16 GBBE9-B0-MEX1.5

17040316

18 0341816

19 y8t30T-1701020

20 16596

21 16929

22 01281630

23 14973

24 Q4ost2

25. GB21-76-M12x25,

26 J8100-1701015

27 aorta

28 601056

29 gaott6

30 92821616

31 16566

3219694

3314749

34 JS190T-1701108

35 JS1307-17011318

36 JS118TB-1701130B

37 J81307-17011128

38 JS100-1701111

39 J8130T-17011218

40 18701

41 J81307-17011058

4205280310

43 12ust60T-1701170

(shanna Fast Gear Co, Lt

Name

Transmission housing assembly

Bale plate assembly, countershatt

#1 clutch housing assembly

Input shaft assembly

Main shaft assembly

Countershaft assembly

Reverse countorshaft assembly

Shift bar assembly

Double-H device assembly

Rear cover assembly

Drive gear, aux. assembly

Clutch release busting

SAE! clutch housing

Bale plate, bearing, countershat

Gasket, side PTO opening

Hex nylon lock nut

Spring washer

Nut

Cover, PTO opening

Cover, bottom PTO opening

Gasket, bottom PTO opening

Doubie-head bolt

Round magnet

Spring washer

Hex bolt

Transmission housing

Fat washer

Double-head bolt

Washer

Flat-end tighten bolt

Guiding sleeve, main shaft

Input shat

‘Shim, spline, gear, main shaft

Reverse sliding sleeve, main shaft

3° gear, main shaft

2 gear, main shaft

1 gear, main shaft

Reverse gear, main shaft

Hex key, main shaft

‘Adjusting shim, gear, main shatt

Main shat

Elastic column pin

4/2.synchronizer assembly

Oty junit

‘i

2

3

8

8

1

8

6

6

2

1

1

1

1

1

1

1

1

1

1

1

1

1

tH

Part Name

45

8

a7

48

49

50

st

52

53

54

56

56

a

58

et

66

@

6

@

70

n

2

73

™

%

6

7

8

79

80

at

2

83

a

799666

“a

J81307-1701180

saust60T-1701122

42U8160T-1701123

J81187B-17010318

481907-17010518

481187B-17010608,

19198

481307-17010488

4J8118TB-17010568,

4§81307-17010558

(05280514

01025

448100-1701088

14287

4§8100-1701082

16405

a2goi2t2

002002

Fose6s

8774

8968

99671

1634

3220

11086

16132

J81307-17020658

J81307-17020558

J81307-1702056-1

4¥81307-17020668

Fo6084

96085

F99588

F99589

48130T-1702015

x-1-603

1276100868-7308

19.05610086B-T308

0351810

0361810

r420802

Fosiad

Sie

3/4 synchronizer assembly

Shim, spine, gear, main shat

28, gear, main shaft

Gear, input shaft

3rd gear, countershatt

‘2nd gear, countershatt

‘Stop ring, countershaft

CCountershaft

Drive gear, countershaft

‘Square key, countershaft

Eastic column pin

Bushing

Cup-shaped reverse washer

Needle bearing

Reverse mid gear

Reverso countorshatt

Flat-end tighten bot

Low reverse fork assembly

Low reverse fork

Reverse lock spring

Reverse lock screw plug

Reverse lock colurmn plug

Fork shaft jointing pin

Shifting fork lock bolt

Double-nead bolt 3/82

Low reverse fork shaft

12 tork sat

41/2 tork

23/4 fork

3/4 fork shat

Compressed spring

Compressed spring

1/2 and 5/6 guiding block

3/4 and 7/8 guiding block

Shifting bar

Hex nut

Stee ball

Stee! ball

Hex nut

2type hex nut

Hex bolt and spring washer assembly

Housing, double-H control device

ls es pr i a a a yan ns sR 9 sr 00 RLM no ps oo —

e plate

i

No.

a7

88

89

0

ot

92

93

95

%

7

8

99

100

101

102

103

104

108

106

107

108

109

110

in

112

113

114

115

116

17

118

119

120

121

122

128

128

128

126

127

128

129

art Number

F99870

Fo1363

Foa5es

Foetat

F99681

(03004

040310

15278

F36035

(040306

F39675

Fa9873

98037

55522

40408

(003030

99679

Fa9669

Fa9674

F96140

99660

Fa134s

96036

55518,

7385

roi4as

Fo9672

99983

341810

are224

2tga0st8

rs1B0812

ar51B1050

‘09035

8-C09006

cot032

19109

7992

Fesge7

-c09009

B21-76-Mt0X75

stt8-1707047

18870

‘© Shaanxi Fast Gear Co, Ltd.

Pari Name

Locating column plug

Gasket, double-H air vale

Siting block

Spring press cover

Control black, low reverse switch

Stop bott

Spring washer

Vent plug

LAC outer shafting arm

Spring washer

Locating ring

Spring seat

Compressed spring

‘Ar pipe assembly

Spring washer

Column pin

Horizontal shifting lever

Bushing

Spring bushing

Gasket

Double-H air valve

Bushing, horizontal shiting lever

Compressed spring

‘Air pipe assembly

Vent plug 1/8?

Oil seal

Ending gasket

Compressed spring

*-type hex nut

Bowl-shaped patch

Inner hex bott

Hex bolt

Hex bolt

Elastic column pin

Rear bearing, main shaft assembly

Ol seal, rearing cover, main shaft

i seat

Bushing, driven gear, speedometer

Cover, rear bearing, main shaft

Bott assembly

Hex bot,

Lengthened countershaft welding assembly, aux

Drive gear, countershat, aux.

junit

48118-1707048

-c09008

17108

682-76-mi0x32

19709

A-CO9005

A-4997

20320

20321

4-498

20322

14323

20323

14897

A-CO9016

usi18-1707120

J8118-1707121

14327

14331

14332

16775

17378

F99882

1923106

16723

14347

17352

19866

96006

F99975

717813

15532

017181250

1421075

cogosa

coi019

16628

16198

18869

01033,

50118

1565

Pari Name

Lengthened countershatt, aux

Bolt assembly

Copper washer

Hex bott

Seal

‘Synchronizer assembly

‘Low-speed synchronizing cone ring assembly

LLowspeed cone ring, synchronizer

Reverse lock pn, synchronizer

High-speed synchronizing ring assembly

High-speed synchronizing ring

High-speed look pin, synchronizer

Siding sieve, synchronizer

Compressed spring, synchronizer

‘Aux. cylinder assembly

Reduction gear assembly, main shaft, aux.

Reduction gear, main shat, aux.

Stop ring

Gear shim, main shaft, aux

‘Washer, main shaft, aux

Fork, aux,

Cover, lengthened countershaft

Main shat, aux.

Roller bearing

Stop ring

Seal

Gasket, bearing cover, countershatt, ux,

Shim, reduction gear, aux.

Flange nut

Rear cover

Roller bearing

Gasket, rear bearing cover, malin shaft, aux.

Hex bolt

Hex bot and spring washer assambly

Hex bolt and spring washer assambly

Stop ring

Stop ting

Locating plate, bearing, aux.

Drive gear, awe.

Fixing battle ring

Ball bearing

Cover, hand hole, clutch

Part Number

1642

4025

so6st4

9293

co4oa2

11665

sa182

12817

12880

cosos2

12845

14282

14083

44811

14317

14334

14335

14918

15899

16763

18769

193 20815

194 20822

195 51016

195 JS118TB-17020228

197, Fa1054

198 F91055,

199 F91409

200 91410

201 F93060

202 Fo1008

208 A-Co9018

204 Fa6005

205 FOBT

208 F99702

207 F99902

208 X-6-11

208 X-7-603

210 xta12

ati Jt18TB-17020218

212 42007E

213° 1023088

214 _ 370309¥

|__estaanxi Fast Gear Co,, Ltd.

Pari Name

Gasket, operation opening

Tension spring

Clutoh release ball bearing

‘Return spring, bearing

Seat, cluch release bearing

Single-pipe hoop

Double-pipe hoop

Ctutoh release fork

45° elbow connector

Tee connector

90" elbow connector

Reverse antthrust washer

Reverse countershaft washer

Gasket, bearing cover, input shat

Stop ring

Locating pin, rear cover,

Gasket, rear cover

Gasket, shift bar

Switch stating pin

Stop ring

Doubie-pipe hoop

Hoisting bent pate

Gasket, clutch housing

Oil pipe assembly

Small name label

Drive gear, speedometer

Driven gear, speedometer

Bearing cover, input shaft

Oil seal, bearing cover, input shaft

Connector assembly, speedometer

Oil sea

Connector assembly, speedometer

Washer

Dust proot

Neutral switch pin

Output flange

Semicircle key

Hex bolt

Speedometer lagging

Name label

Roller bearing

Roller bearing

Ball bearing

Oty funit

Wa,

215

216

27

218

219

220

22

202

223

2204

205

228

207

208

2203

230

231

282

233

234

235

238

237

238

239

240

2m

282

243

24

245

248

aur

248

249

250

251

252

253

254

255

255 _GuSI6OT-1709587-1_Opug

Part Numb Part Name

as080812 Hox bolt

arazioge Hex bott and spring washer assembly

ar4z10gem Hex bott and spring washer assembly

ar4si0s2M Hex bol, spring washer and fat washer assembly

1421038 Hox bolt and spring washer assembly

razi04s Hax bott and spring washer assembly

01421050 Hex bolt and saring washer assembly

1461050 Hex bol, spring washer and fat wesher assembly

(G827-88-M10K32 ‘Hex bolt

n4z1236Mm Hex bolt and spring washer assembly

av4et290M Hex bolt and spring washer assembly

o1s1B1645M Hex bott

co0a2 Hex bott

1420660 Hex bolt and spring washer assembly

040308 Spring washer

coto20 Stop ring

coto21 Stop ring

02713608 Cross recessed head bolt

GBE90-80-MI6X1.5 Hex rylon lock nut

cosas Hex bolt and spring washer assembly

618801 Hox taper screw plug

votes Grease nipple

6B1154-79-6 Screw al cup

a72sisTa Seal ring

791.00.71.0068 Pressure switch

791.00.71.0068 Pressure switch

990.12.71.0081 Pressure switen

ccosoos sacket

coto24 Jacket, bearing, input shaft

cos0ts Seal ring

cosot6 Switch lagging

03025 Shaft lagging

cosor3-1 Oil evellabel

8858 Nut, input shat

14750 Stop ring

180212K Bal bearing

1463 Gear pad

-c03002-11 Air fiter austor and screw plug assembly

sorta Fiat washer

@/St60T-1709588-1 O-ring

4

8

"

mmae

AD:DaQingRoad, Xi'an, Shaanxi China

Tel:0086-29-84630630 84630629

400-8899-901 800-840-9955

Fax:0086-29-84627086

P.C:710077

E-mail:fastirade@ saggw.com

Http//www.saggw.com

Http//www.chinafastgear.com

También podría gustarte

- Especificaciones del Reenvío QJ805Aún no hay calificacionesEspecificaciones del Reenvío QJ805136 páginas

- Gálibo y Manual de Motor SinotrukAún no hay calificacionesGálibo y Manual de Motor Sinotruk498 páginas

- Copia de Repuestos - Caja ZF 4 - 16s2231 (00000002)100% (1)Copia de Repuestos - Caja ZF 4 - 16s2231 (00000002)4 páginas

- Frontal: Capacidad Del Balde 3 M Capacidad de Carga 5000 KG Altura de Descarga 3090 MM100% (2)Frontal: Capacidad Del Balde 3 M Capacidad de Carga 5000 KG Altura de Descarga 3090 MM6 páginas

- Catálogo de Repuestos de Transmisión AutomotrizAún no hay calificacionesCatálogo de Repuestos de Transmisión Automotriz46 páginas

- CAMION DW90A (Yuchai III Allison4800 Hande Axle) OM 202111000-SPAún no hay calificacionesCAMION DW90A (Yuchai III Allison4800 Hande Axle) OM 202111000-SP156 páginas

- Reparacion Allison 4-1-30 EspañolAún no hay calificacionesReparacion Allison 4-1-30 Español30 páginas

- Cargador ZL50G-7: Especificaciones y UsoAún no hay calificacionesCargador ZL50G-7: Especificaciones y Uso4 páginas

- Manual de Partes Eje Trasero GR (MERITOR)100% (2)Manual de Partes Eje Trasero GR (MERITOR)23 páginas

- Series TT 2220 Parts Catalog Sa 1133 Trans Alisson100% (1)Series TT 2220 Parts Catalog Sa 1133 Trans Alisson45 páginas

- FHB320B - RETARDADOR FAST GEAR - ZH-CN - EsAún no hay calificacionesFHB320B - RETARDADOR FAST GEAR - ZH-CN - Es10 páginas

- Excavadoras SANY: Eficiencia y ConfortAún no hay calificacionesExcavadoras SANY: Eficiencia y Confort9 páginas

- Guía de Mantenimiento para GrúasAún no hay calificacionesGuía de Mantenimiento para Grúas458 páginas

- HW13709XST、16709、19709 Manual de RepearcionAún no hay calificacionesHW13709XST、16709、19709 Manual de Repearcion163 páginas

- Plan de Mantenimiento PM01 - Retroexcavadora XCMG - XT 870 BR100% (1)Plan de Mantenimiento PM01 - Retroexcavadora XCMG - XT 870 BR4 páginas

- Organigrama Del Servicio Técnico IIAún no hay calificacionesOrganigrama Del Servicio Técnico II2 páginas

- Procedimiento para Cambio de Aceite Cajas Automaticas ZF Ecomat 2100% (1)Procedimiento para Cambio de Aceite Cajas Automaticas ZF Ecomat 213 páginas

- Cajas de Cambios Automatizadas y DSGAún no hay calificacionesCajas de Cambios Automatizadas y DSG17 páginas

- Especificaciones y Mantenimiento de TransmisiónAún no hay calificacionesEspecificaciones y Mantenimiento de Transmisión72 páginas

- Transmisión Manual: Conceptos ClaveAún no hay calificacionesTransmisión Manual: Conceptos Clave28 páginas

- Descripción del Transmisión Automática 4R100Aún no hay calificacionesDescripción del Transmisión Automática 4R100148 páginas

- Funcionamiento de Cajas de CambioAún no hay calificacionesFuncionamiento de Cajas de Cambio36 páginas